Prawn farming is a labour-intensive and time-consuming process.

55% of the shrimp we consume are from aquacultures and the demand for farmed shrimp is projected to grow 6% per year. However, only 10% of all shrimp farming is considered sustainable and smallholder farms find it challenging to manage labour-intensive and time-consuming processes like water quality testing and shrimp sampling. A smart aquaculture system can empower farmers to improve the productivity of their farm to meet the rising seafood demand sustainably.

Introducing ShrimpAnywhere

To empower small-scale shrimp farmers and ensure global food security, ShrimpAnywhere was developed to provide farmers with an affordable and sustainable aquaculture solution.

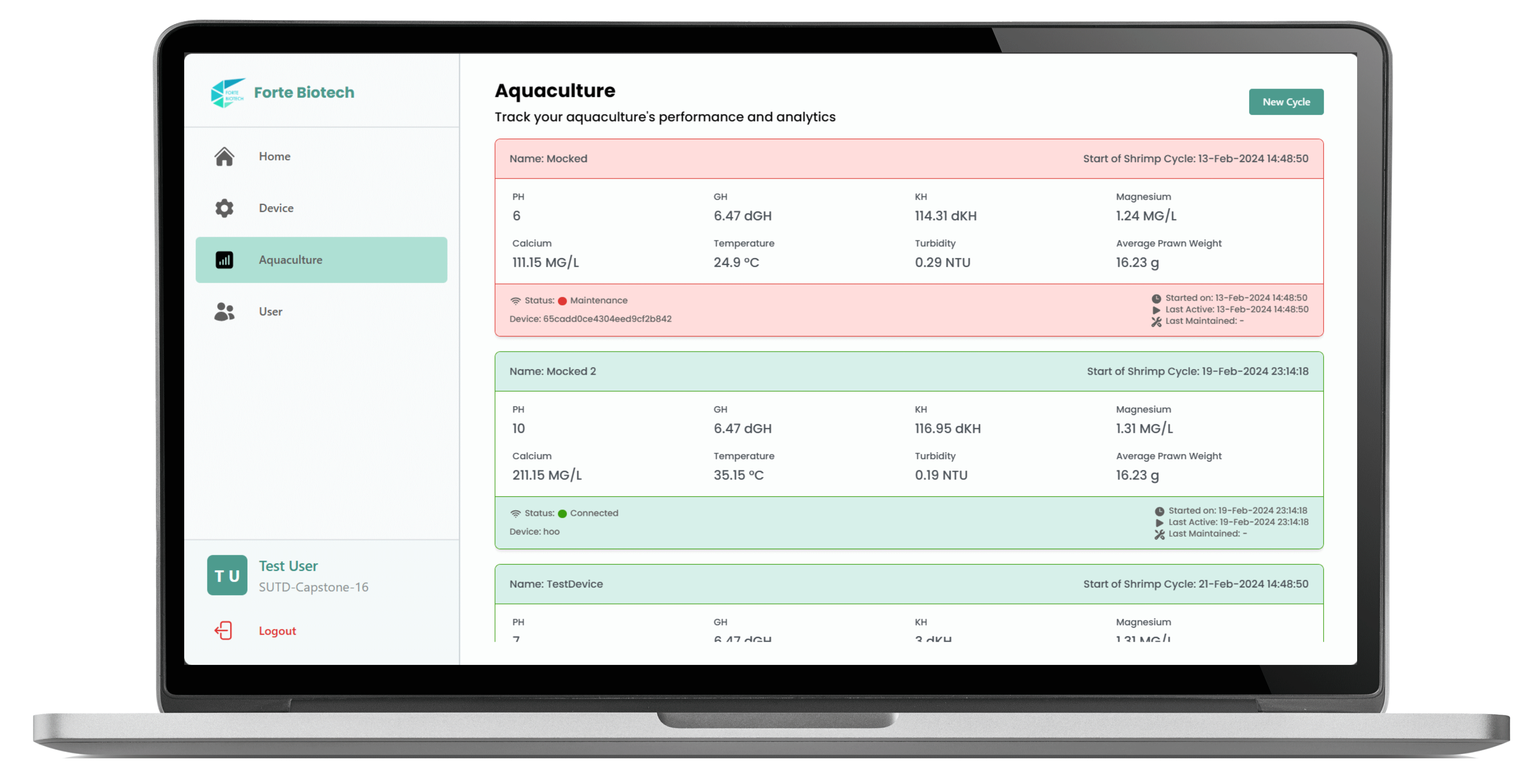

Through high-precision monitoring of water quality parameters and shrimp growth, farmers are enabled to make informed decisions on how to manage their systems. This approach minimizes shrimp mortality and increases shrimp output.

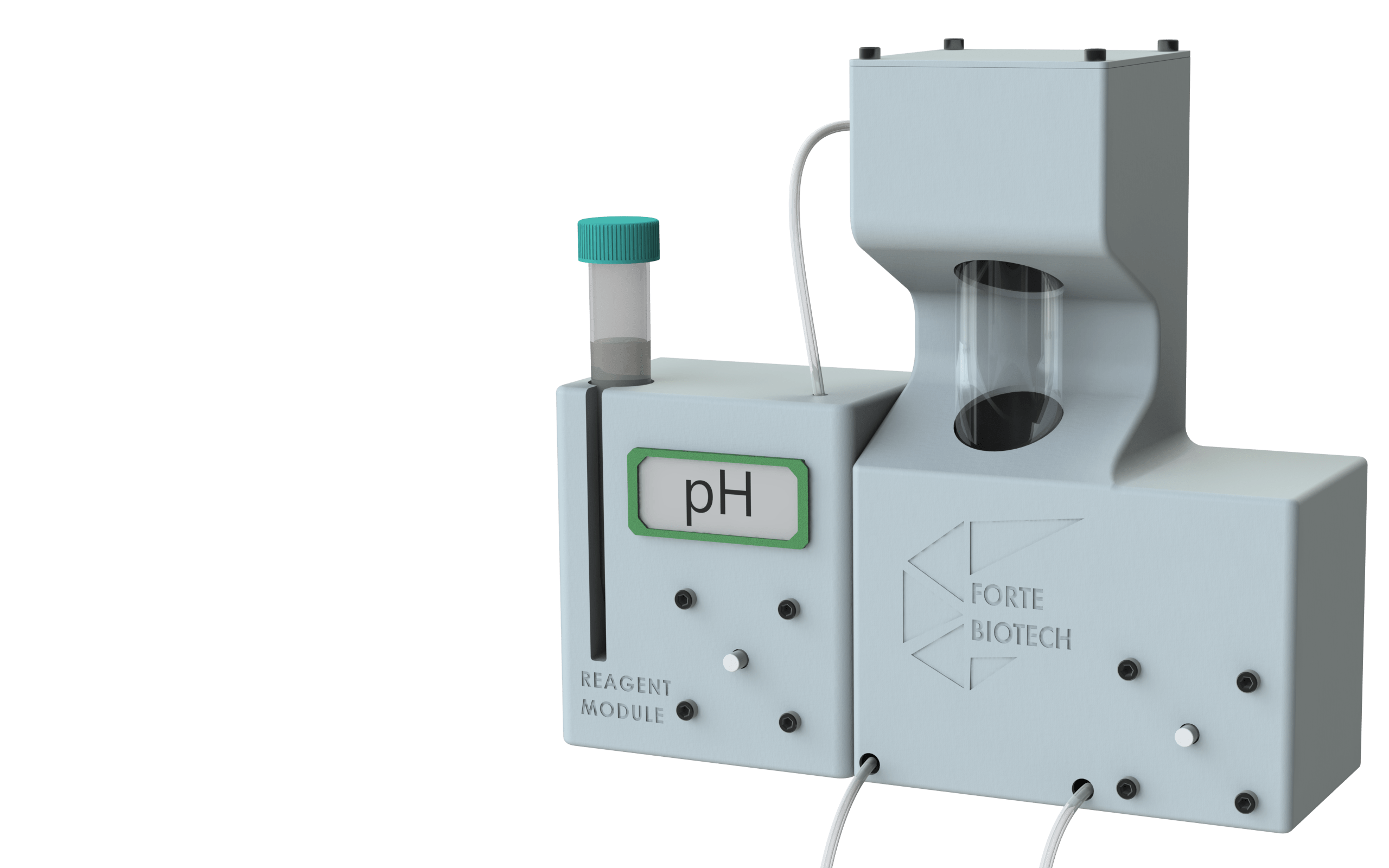

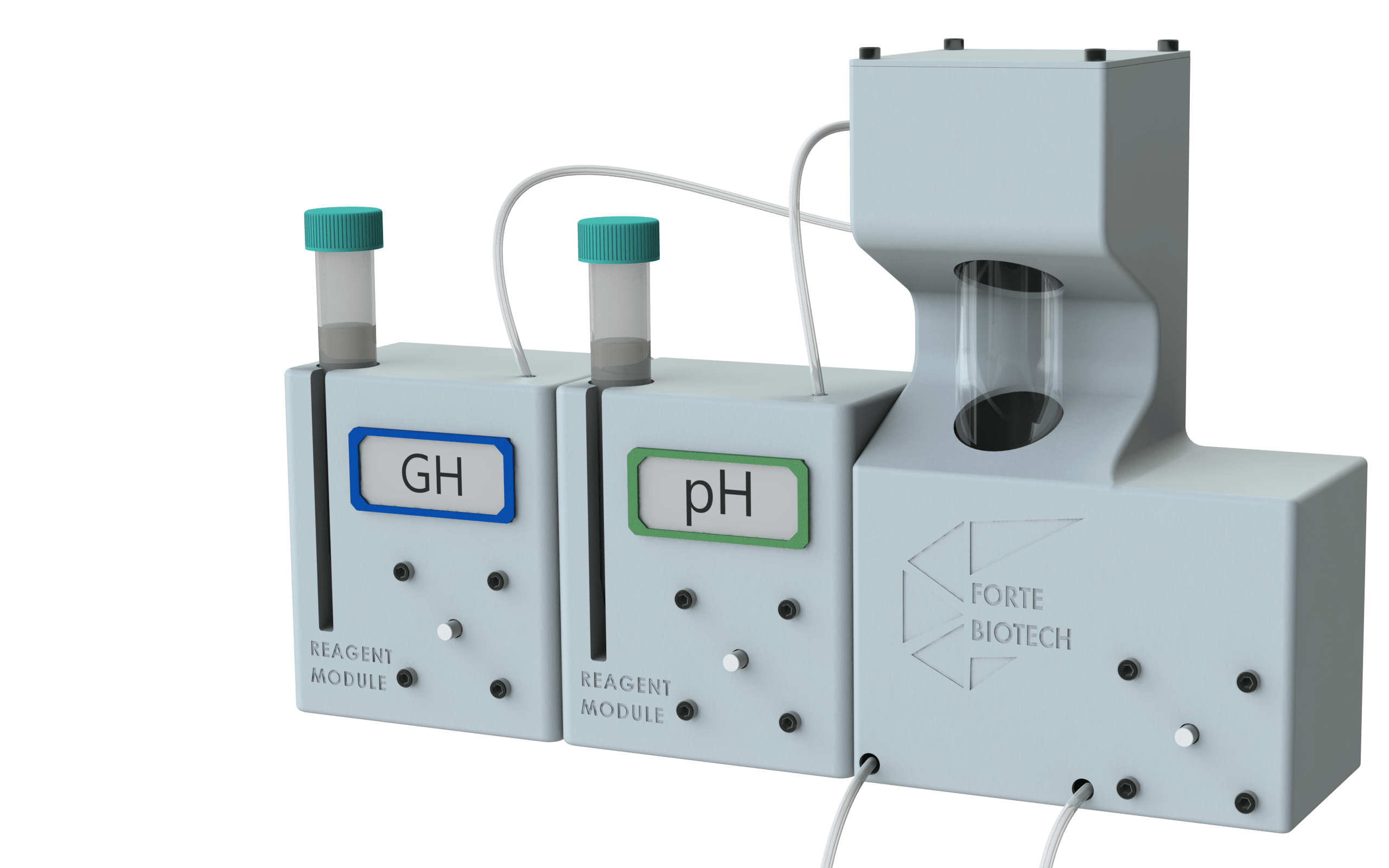

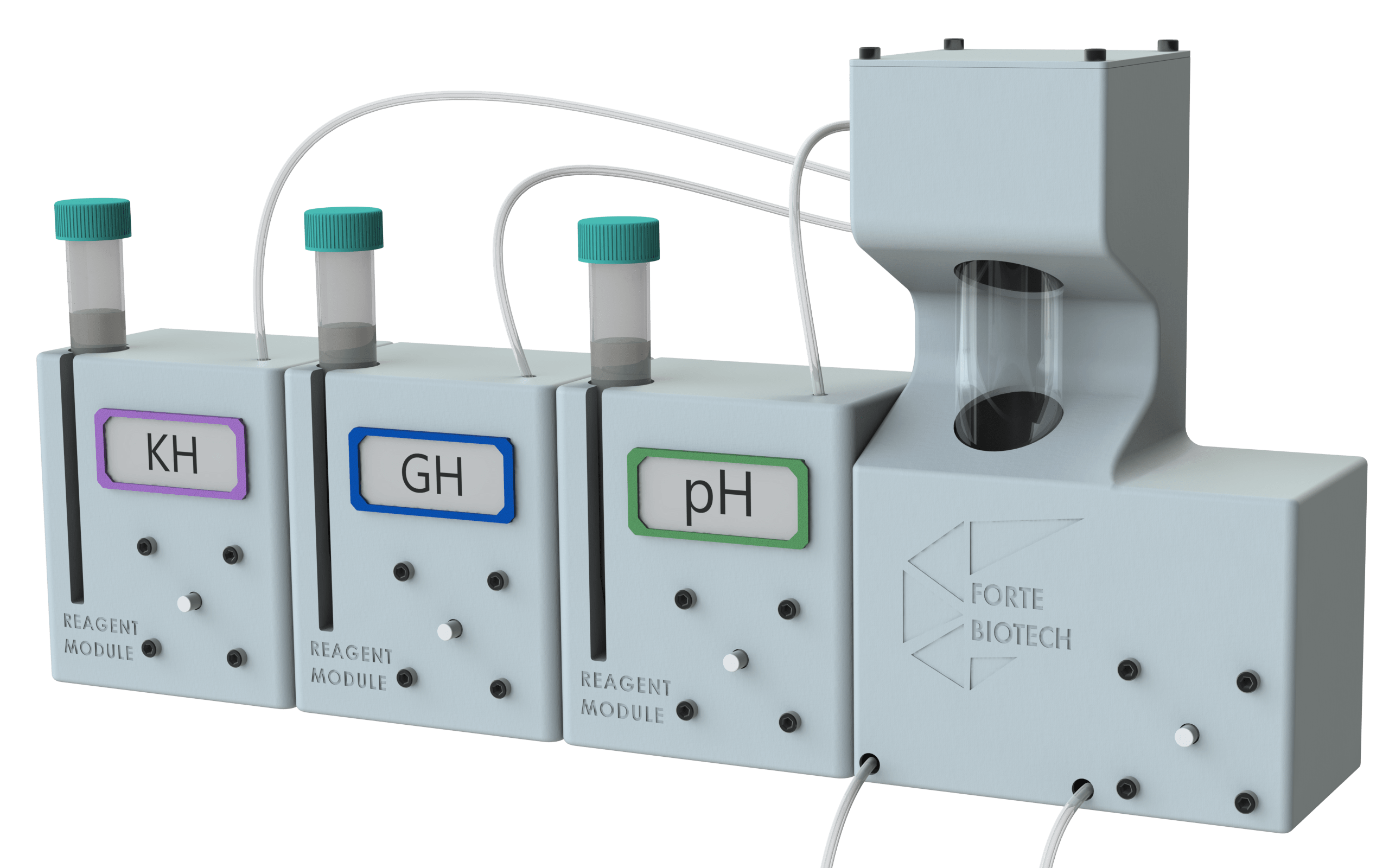

Water Quality Testing

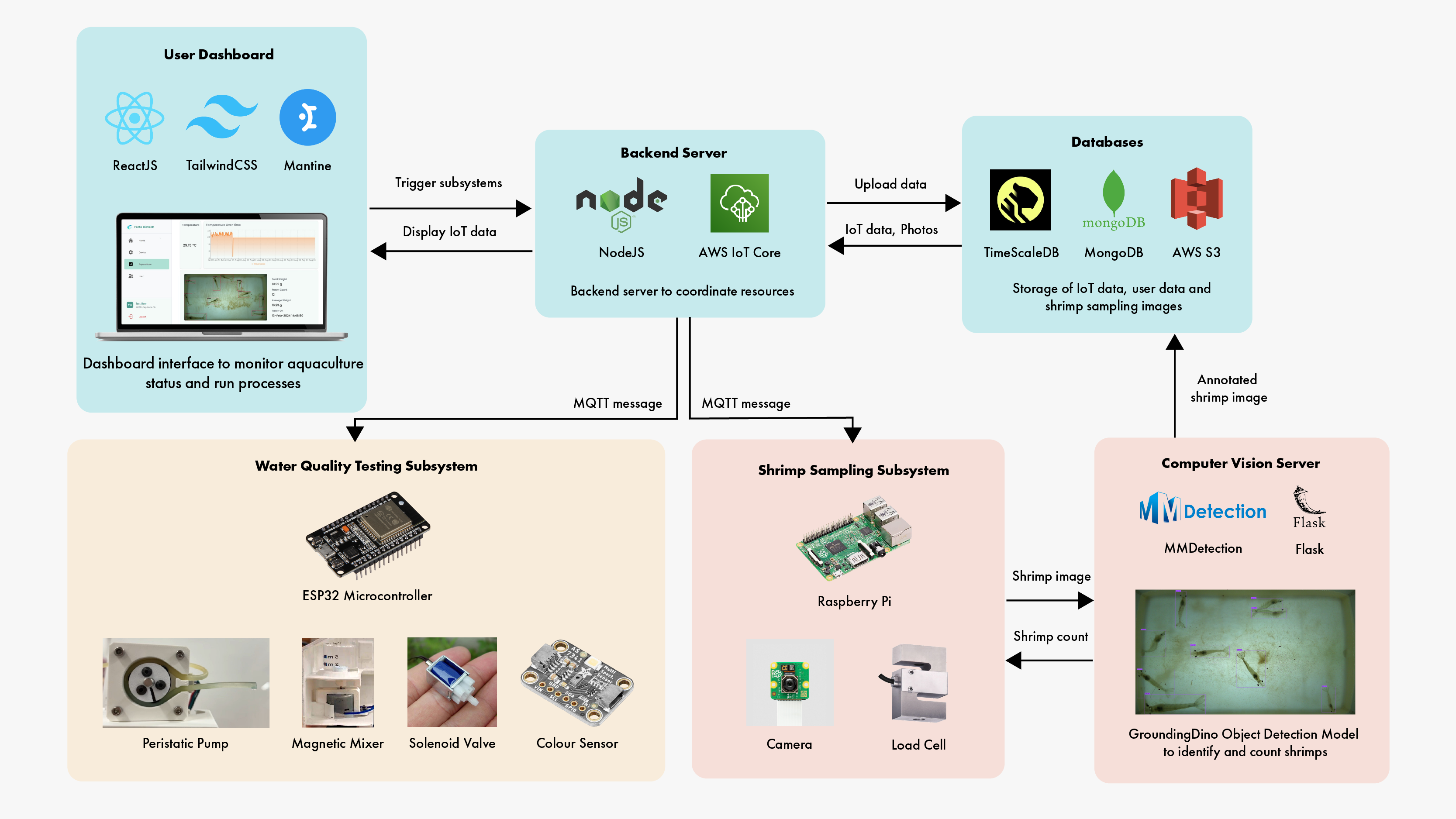

Frequent measurement of water parameters is crucial to maintain the optimal aquaculture environment for shrimp growth. The water quality testing subsystem is capable of measuring a wide range of water parameters including gH, kH, Ca and employs a modular plug-and-play design to allow farmers to scale their testing operations efficiently.

Testing Sequence

Colorimetric tests are fully automated through a three-step sequence that involves drawing water sample from the tank, performing a titration until the expected color change is detected and cleaning the test tube for subsequent tests. Water parameter values are determined from the extent of colour change.

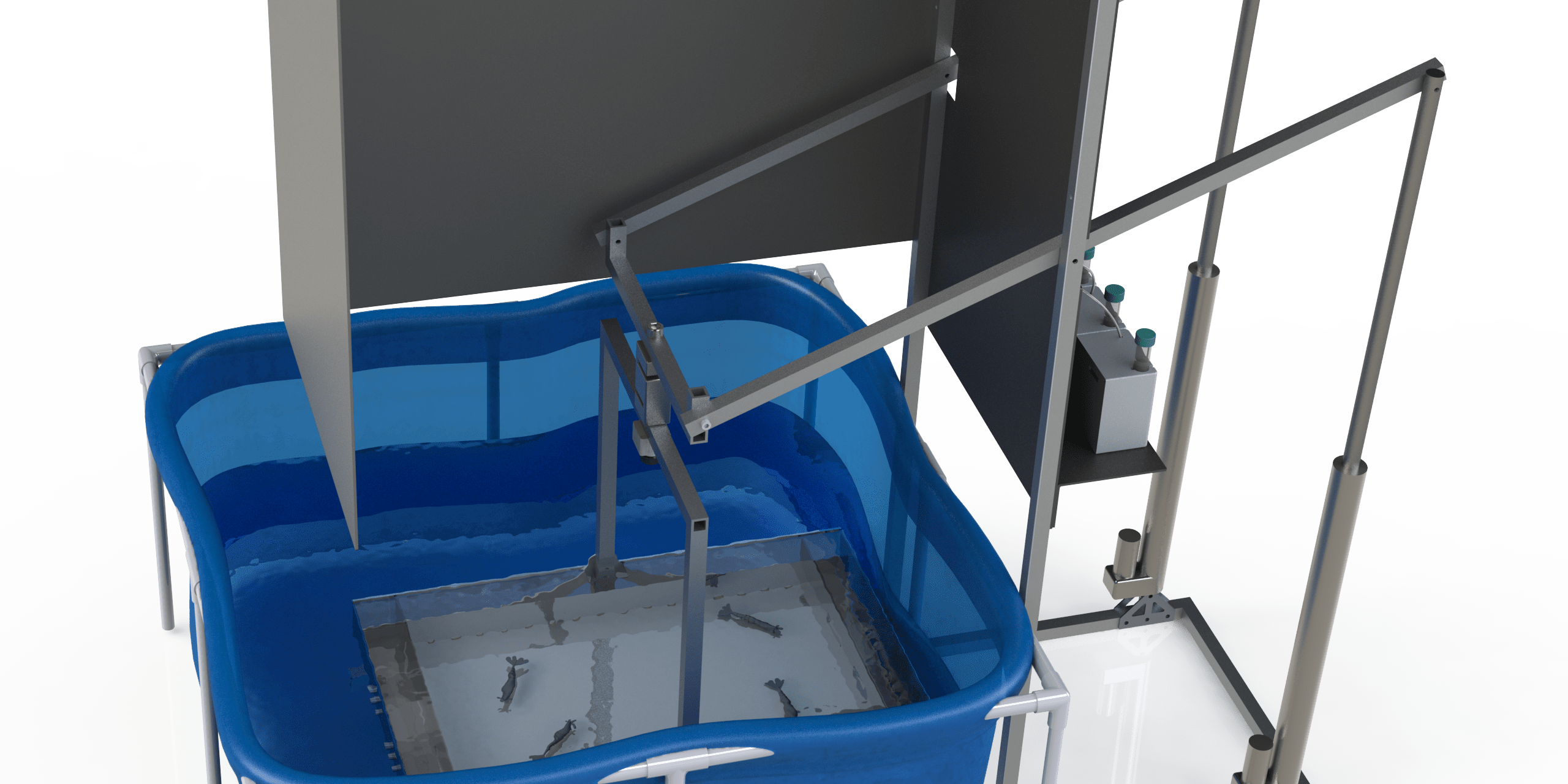

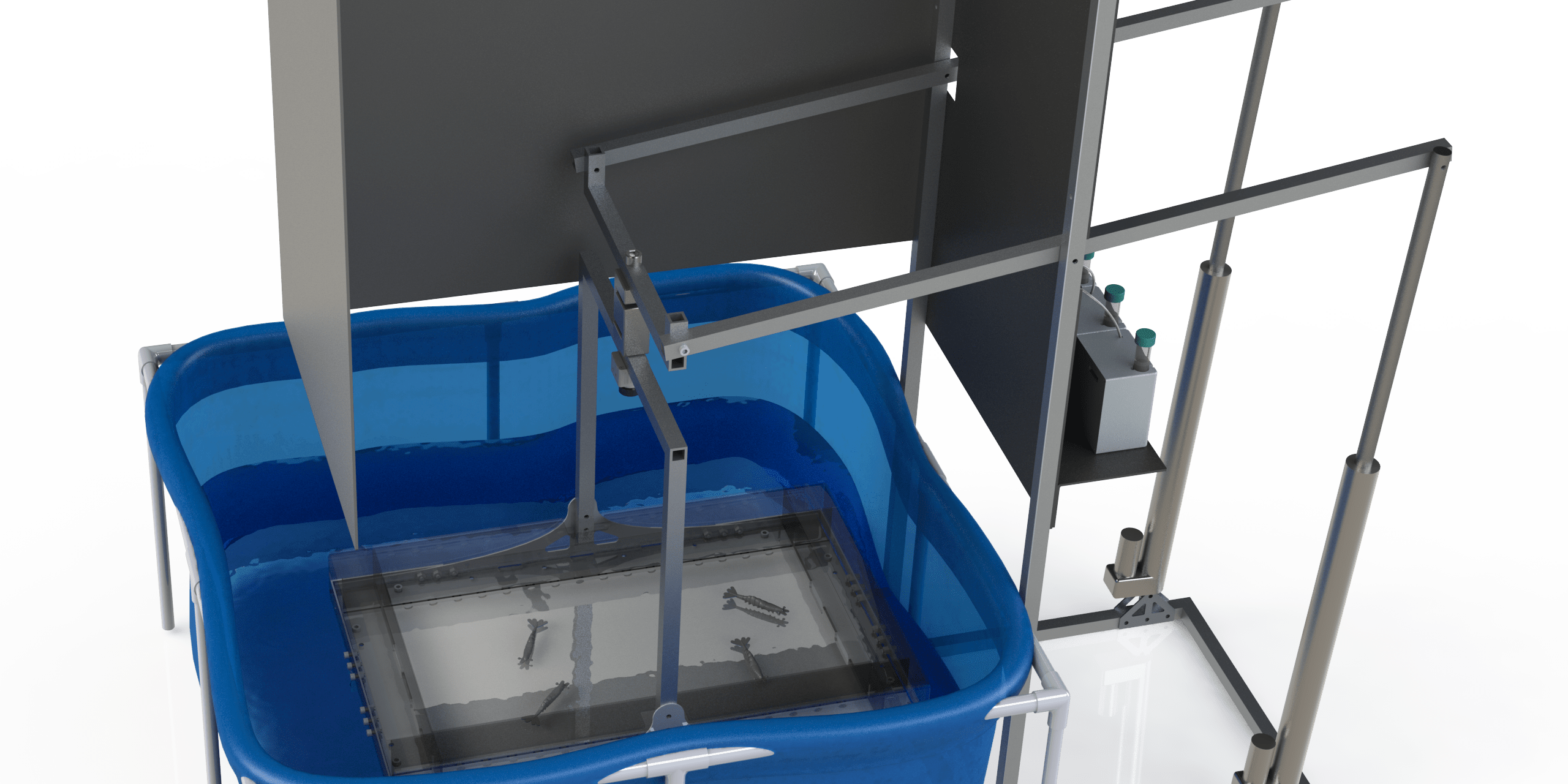

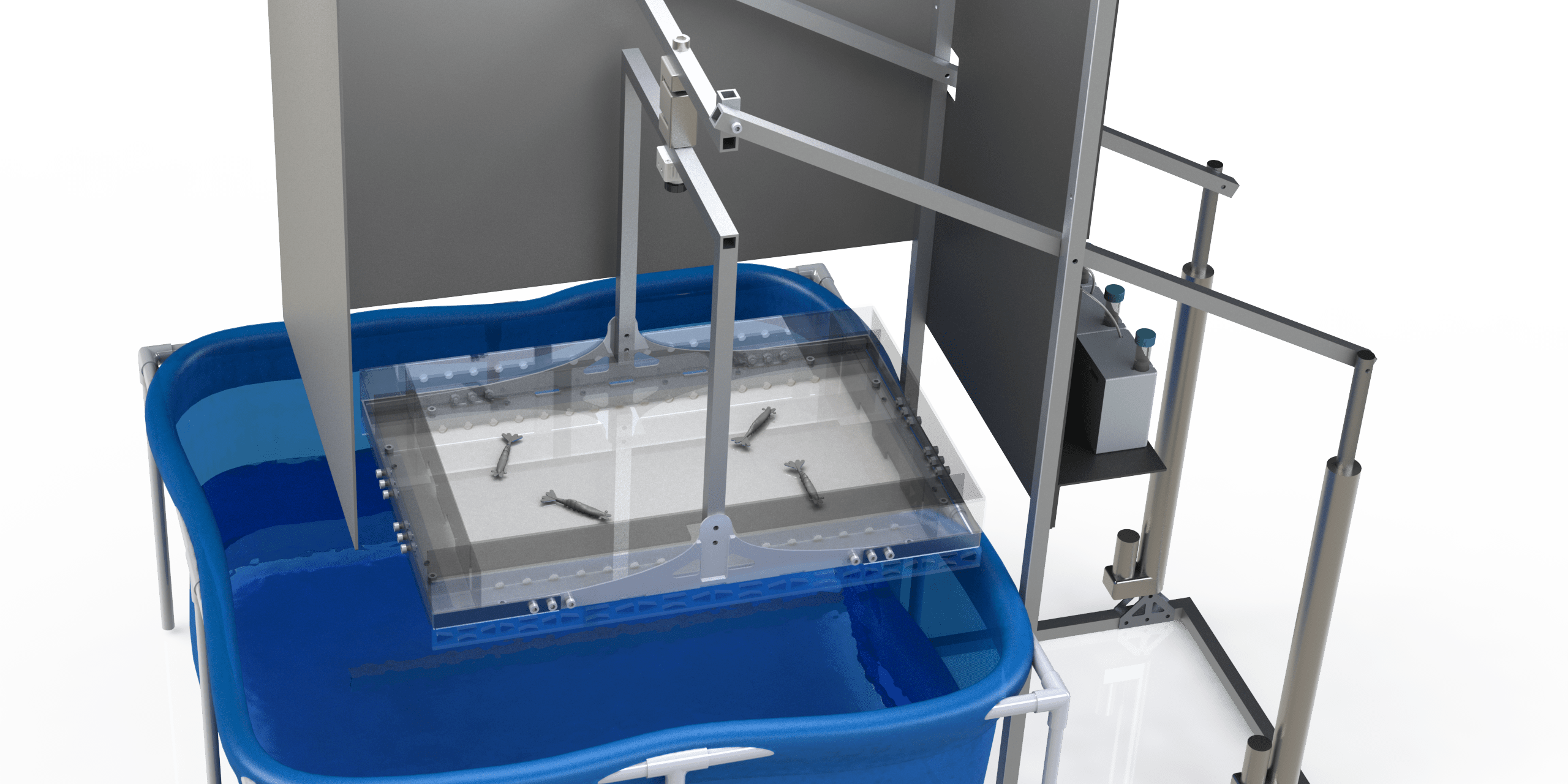

Shrimp Sampling

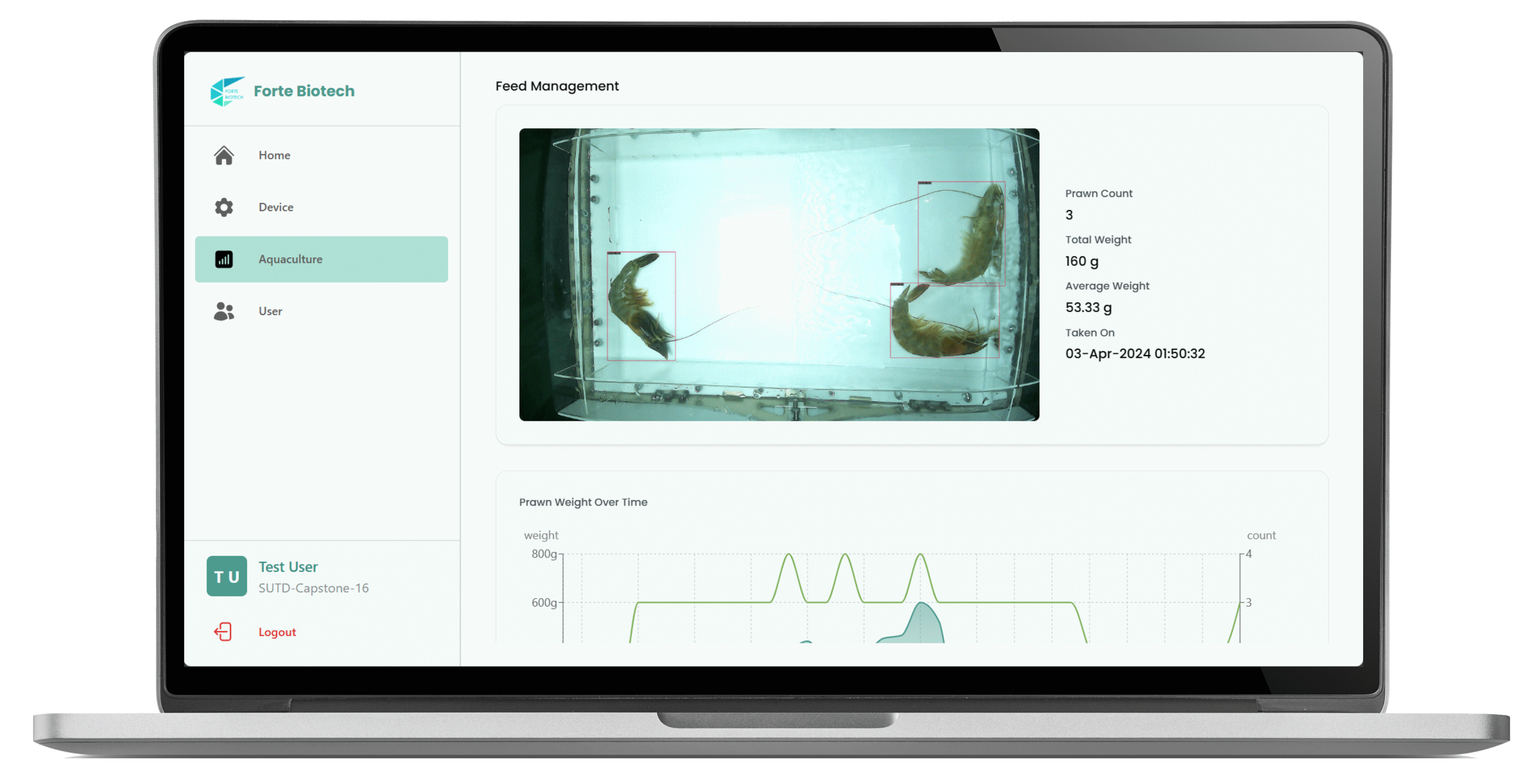

During shrimp production, feed cost accounts for up to 70% of the total operational cost, of which half is left unconsumed by the shrimps. By accurately keeping track of the average weight of the shrimp population, farmers can make better data-driven decisions to identify ideal harvest time and determine optimal feeding schedules.

Sampling Process

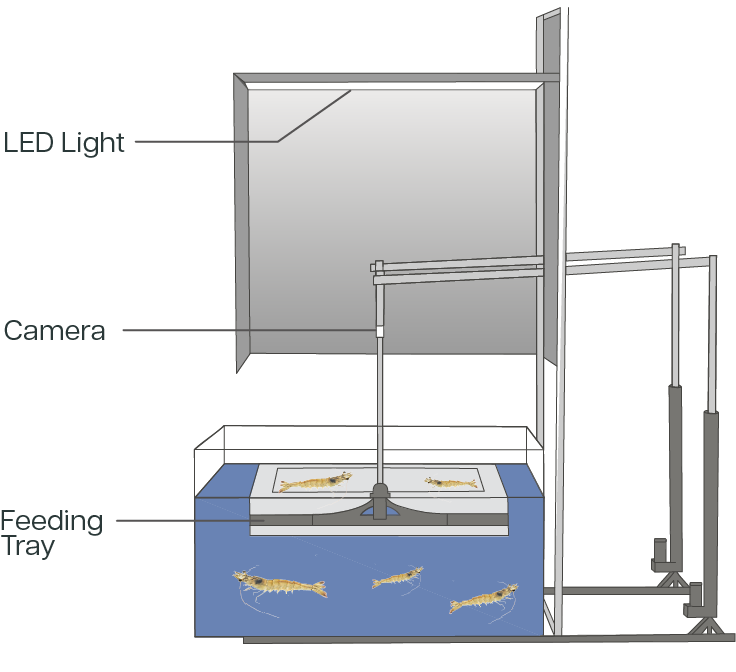

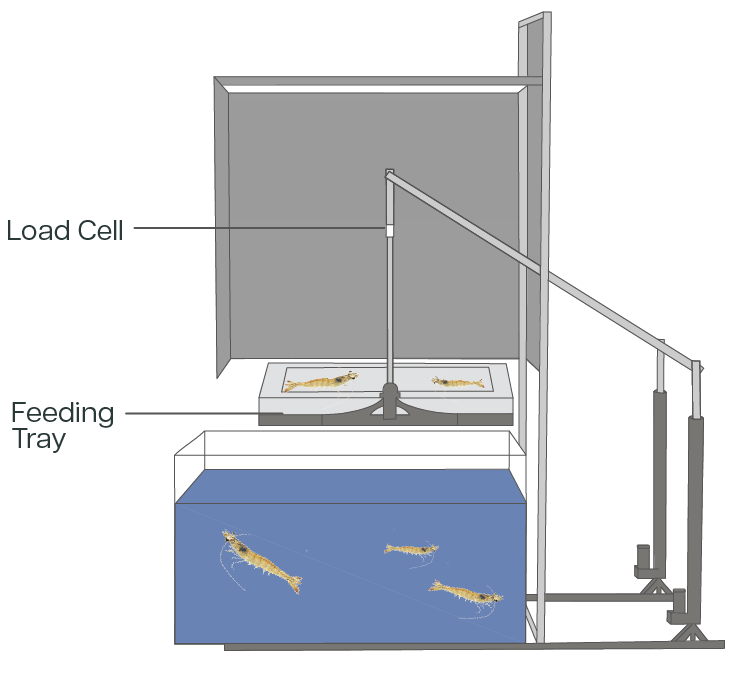

The shrimp sampling subsystem derives the average shrimp weight in a system by leveraging computer vision and a weight sensor to enumerate and weigh shrimps. By eliminating the need for human interaction with shrimps, the autonomous sampling process reduces the risk of bio-contamination and the spread of diseases across aquaculture systems.

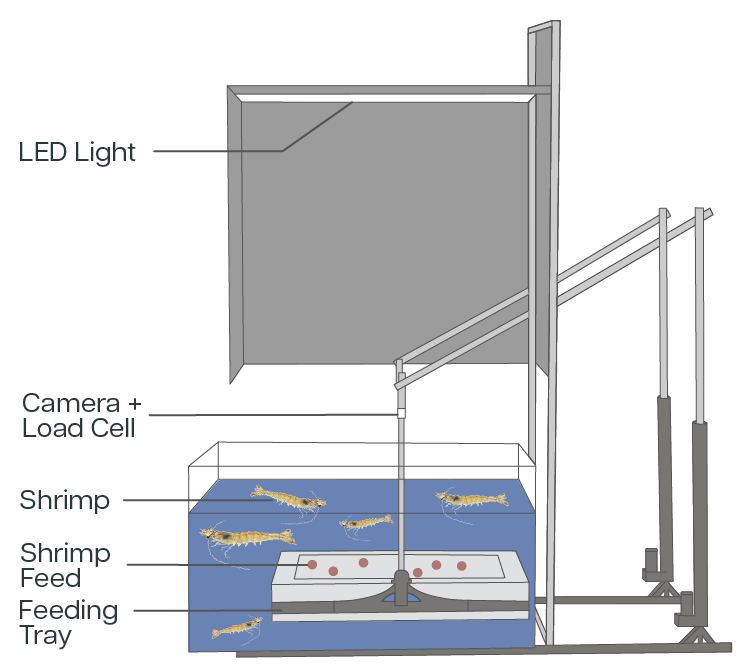

Step 1: Baiting

Feed is dispensed and feeding tray is lowered to bait shrimps into the tray

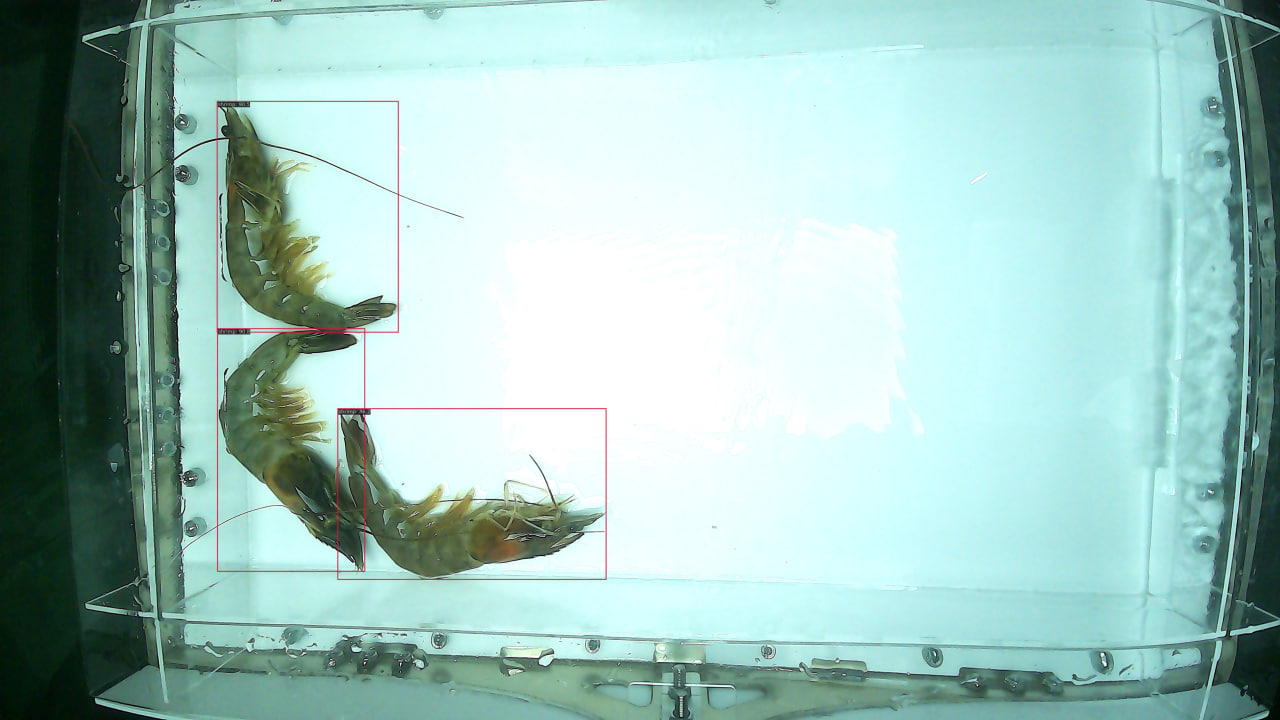

Step 2: Imaging

Backlight is turned on and tray is raised to water level. Image of shrimps is taken

Step 3: Weighing

Tray is lifted out of water and shrimps are weighed using a load cell

Computer Vision

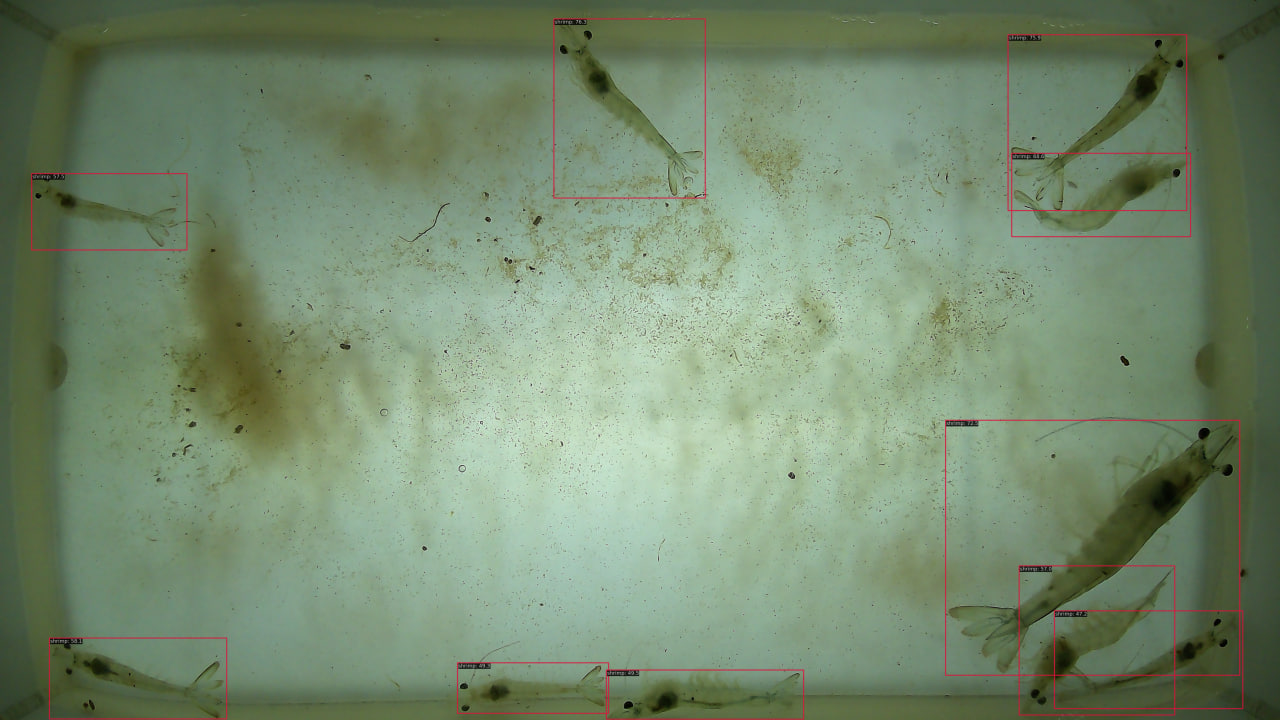

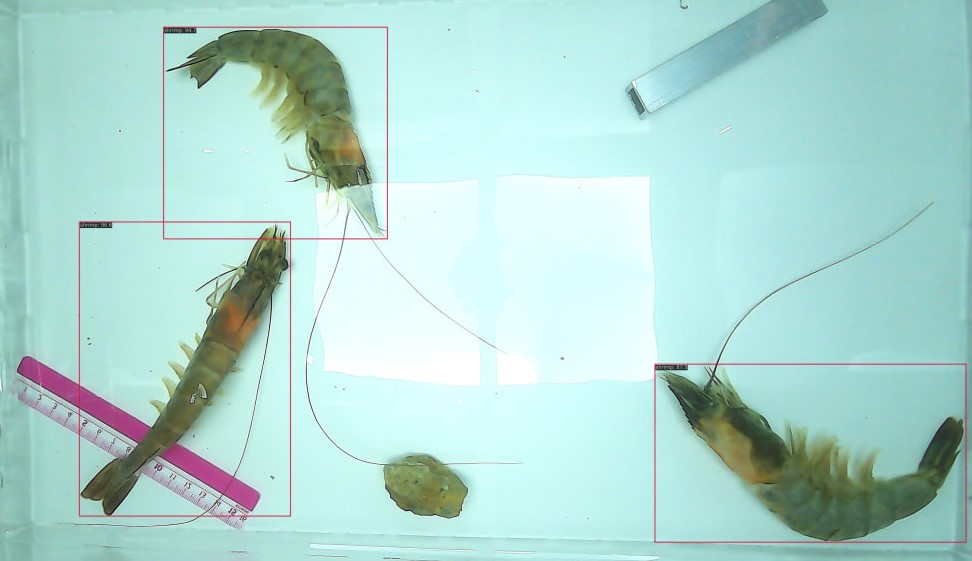

GroundingDINO is a state of the art zero-shot object detection model.

Trained with a custom dataset, the finetuned GroundingDINO model obtained 85% classification accuracy when identifying shrimps in water.

The model has been trained to count shrimp reliably, even when they appear clustered together. It can also accurately differentiate shrimp from foreign objects bearing resemblance in shape or hue through selective feature recognition.

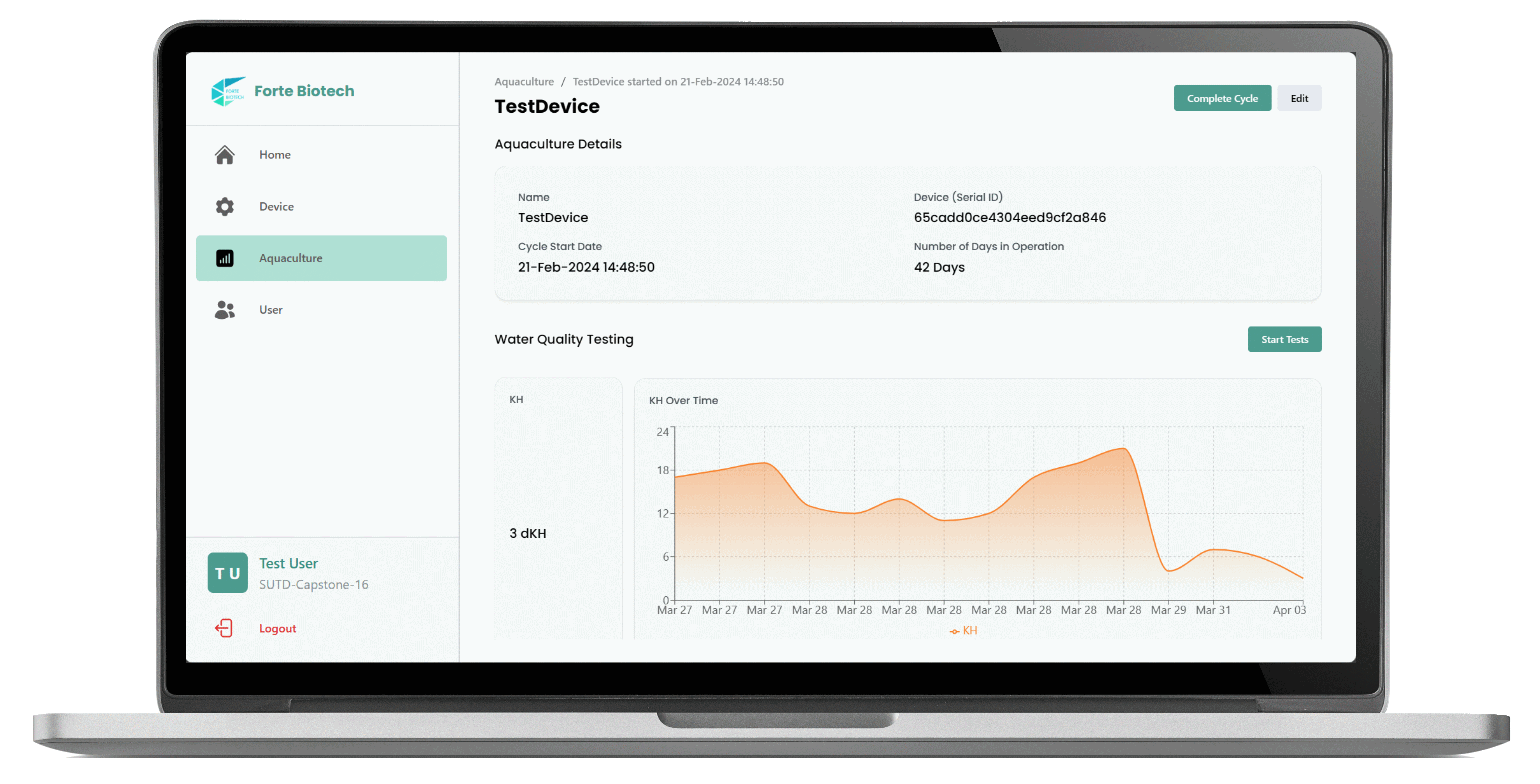

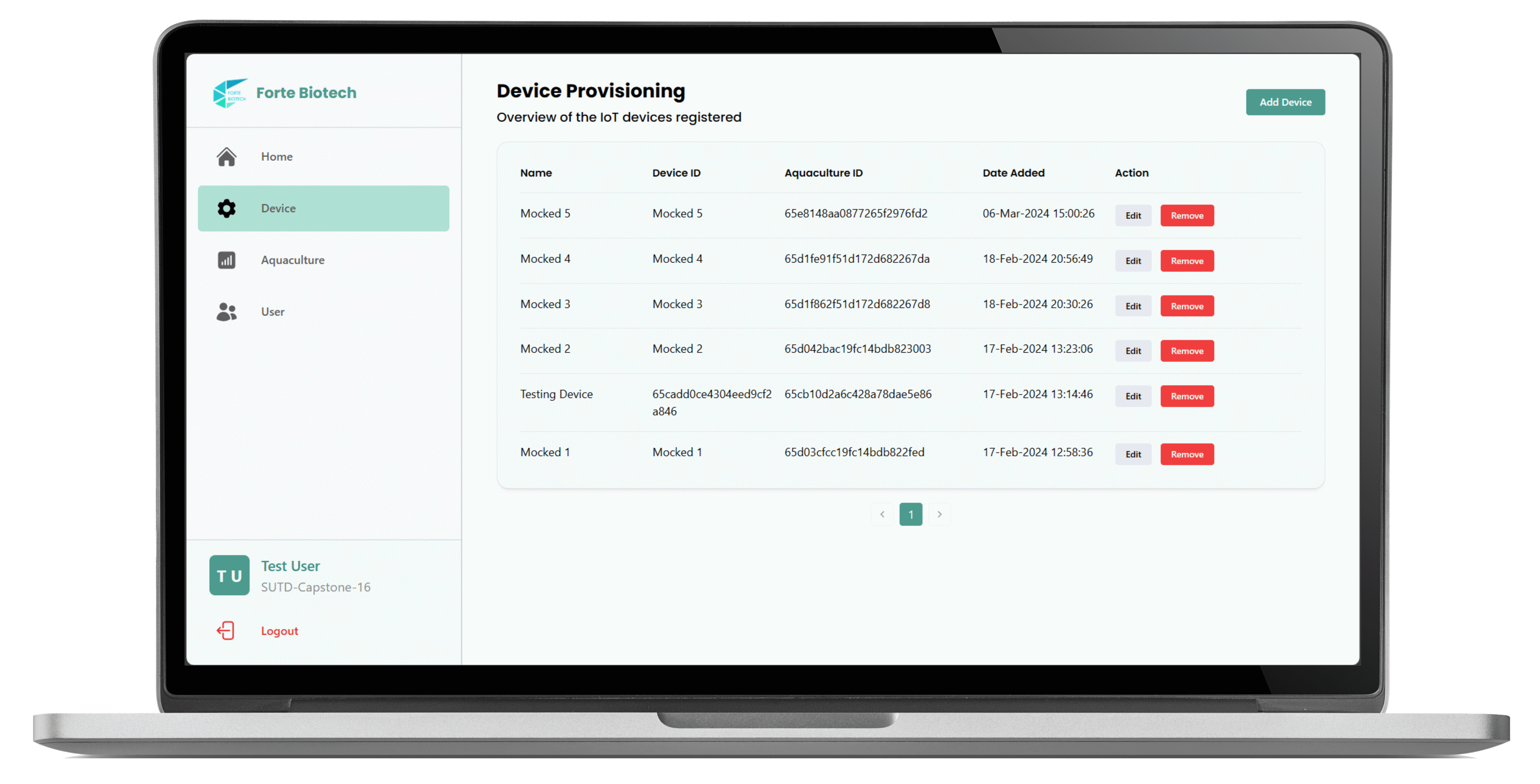

User Dashboard

ShrimpAnywhere's intuitive dashboard consolidates the IoT data collected from the system and allows farmers to visualise trends over time. With the dashboard, farmers have the ability to remotely trigger specific processes on their aquaculture system, enabling them to oversee their aquaculture operations from anywhere, irrespective of their physical location.

System Architecture

ShrimpAnywhere makes use of several core technologies in Internet-of-Things (IoT), computer vision, and data visualisation to transform shrimp farming. An overview of how each technical component interacts within the system is illustrated below.

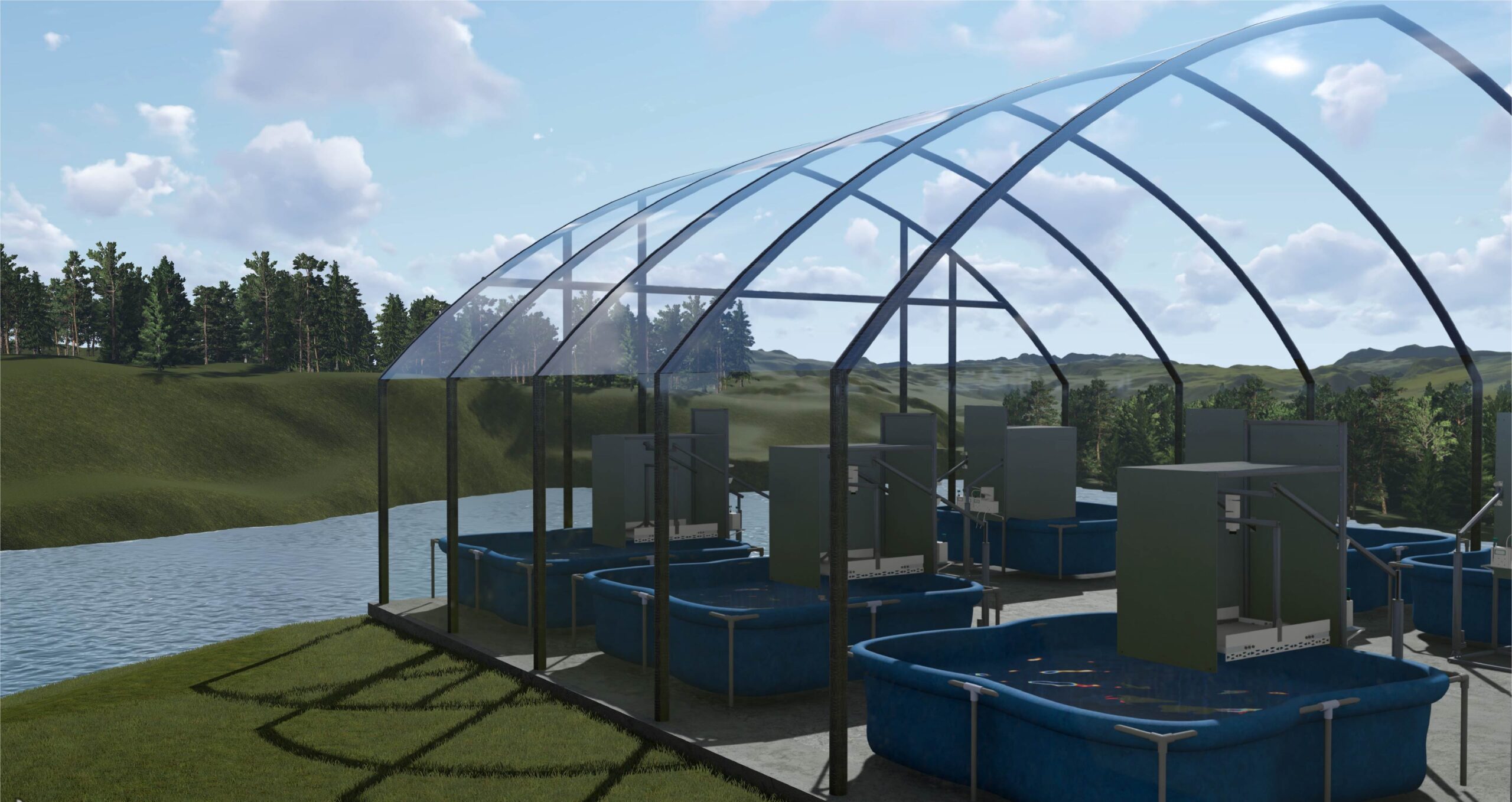

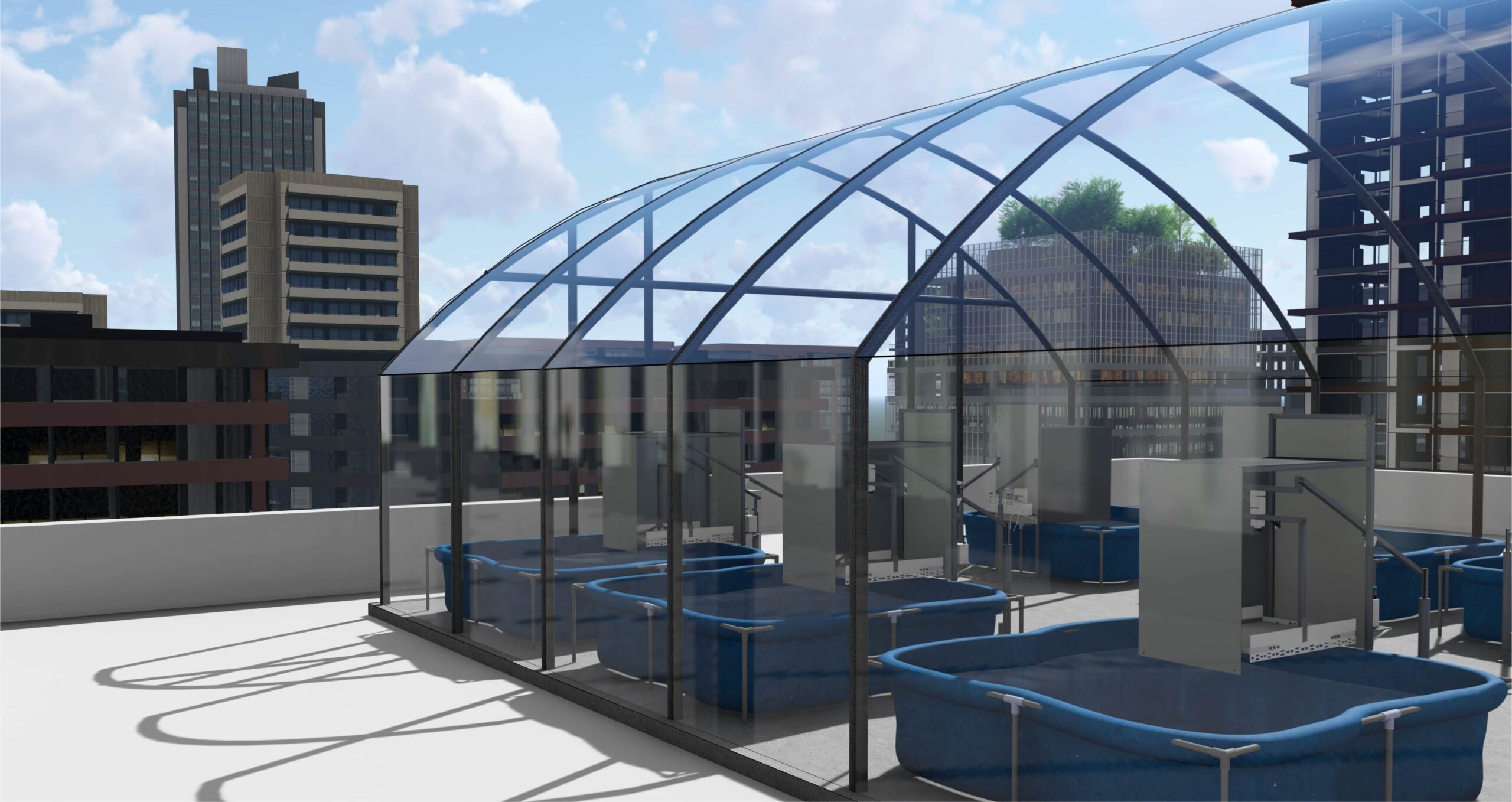

Farm Anywhere

The development of more precise shrimp farming technology facilitates farmers to transition to more technically complex but sustainable methods like Biofloc technology, which uses a culture of microorganisms to recycle bio-wastes into nutrients for the shrimps. These autonomous closed-loop system are less resource-intensive and can be easily integrated into urban settings, offering food security even in densely populated areas.