Project Description

PULSE is an innovative solution developed by a multidisciplinary team to address the challenges of pandemic response. This modular, negative-pressure capable isolation unit can be rapidly aggregated into large assemblies, providing swift treatment and isolation for pandemic victims. With its fully automated structure and adaptable internal configuration, PULSE offers a versatile solution for both clinical and non-clinical needs during pandemics.

The Problem

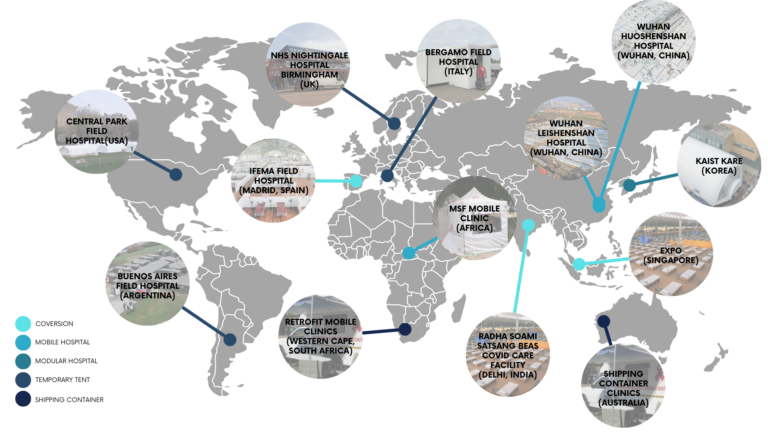

Pandemics are inherently volatile, unpredictable and resource intensive, and put significant strain on existing healthcare infrastructure to isolate and treat infected patients. However, what makes them truly dangerous is the inability of the pandemic response system to swiftly adapt to the changing needs, circumstances and disruptions caused by the pandemic.

During the Covid-19 pandemic, the most dangerous shortage Singapore faced was space – dedicated medical facilities for the isolation and treatment of infected patients. With no reliable forecast of patient numbers, hospitals struggled to provide sufficient bed space during spikes in patient loads, and reduce resource wastage when bed occupancy fell. Large-scale isolation facilities such as NUH’s Covid-19 Annex were constructed, but administrative hurdles and slow construction hindered their effectiveness.

Whilst Covid-19 was indeed highly transmissible, Singapore and the world at large were fortunate that the virus was relatively non-fatal. This stroke of luck allowed us concessions like converting general wards into Covid-19 wards and setting up mass treatment facilities for infected patients.

However, what if we are faced with a more lethal, more contagious virus in the future, that demands more rigorous isolation and forbids our reliance on manpower to se up new facilities?

The Need for PULSE

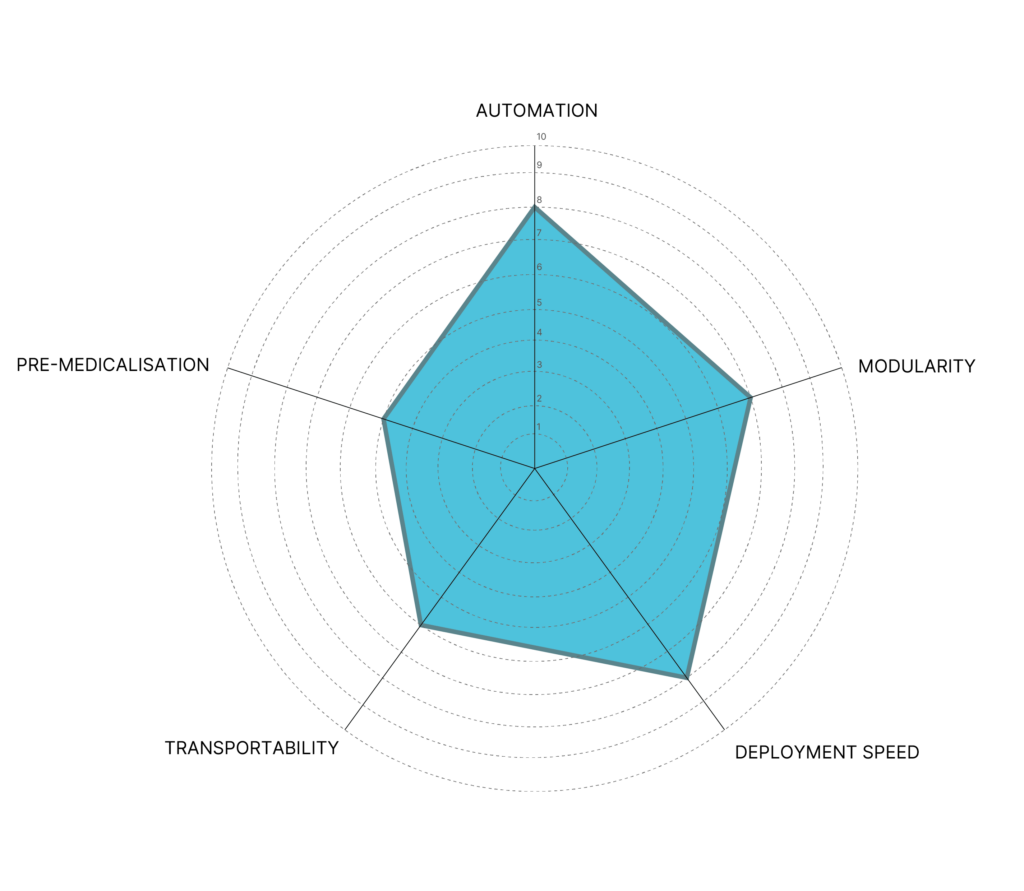

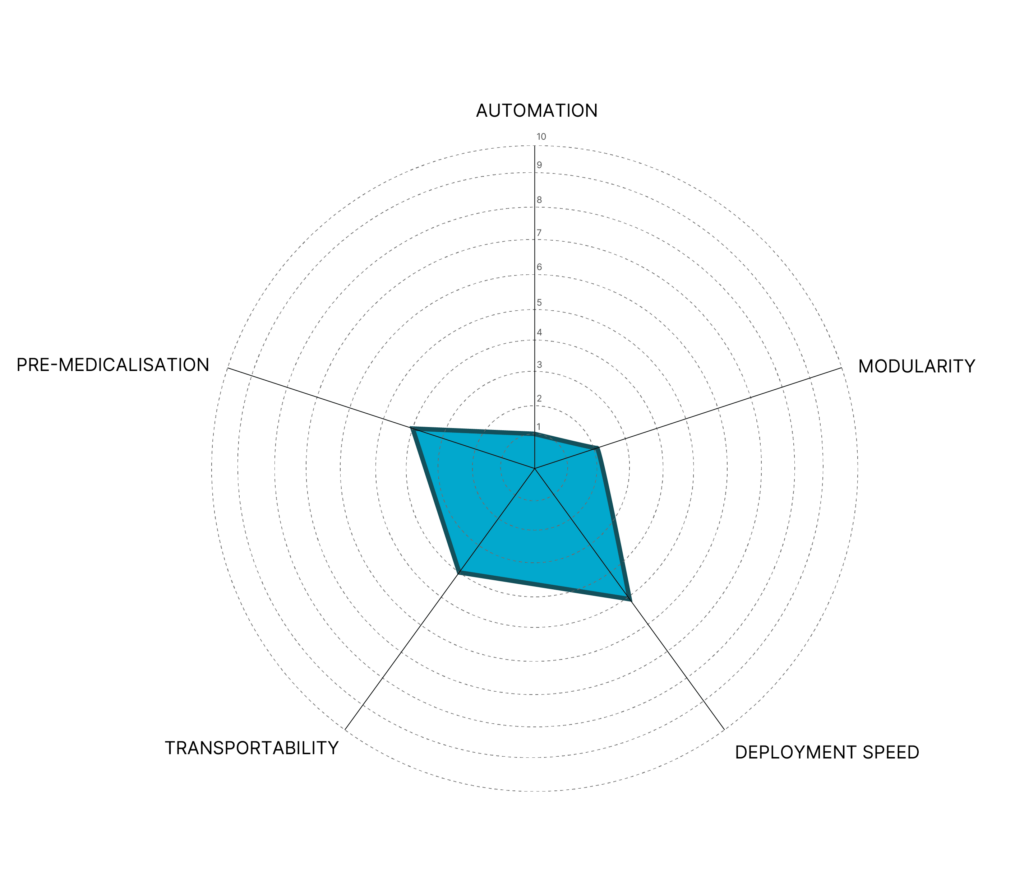

To effectively respond to the threat of such a dangerous pandemic scenario, hospital administrators and health authorities need a deployment-ready clinical solution that fulfils five key needs.

NEEDS

PULSE

- Minimal manpower and heavy machinery required for setup and takedown of solution.

- A high degree of flexibility, allowing the solution to quickly scale up and down on demand.

- Minimally complicated logistics for transportation of solution to and from site.

- As many pre-fitted utilities as possible, with every patient room able to support a wide range of medical procedures.

- As little construction time as possible to quickly operationalise and reduce labour and construction costs.

- Automating key manpower-intensive setup and takedown steps, eliminating the need for cranes and heavy machines

- A modular unit design allowingPULSE to be incrementally expanded and reduced without compromising its operations.

- PULSE units are transport-ready, with all components able to break down into easily-assembled parts.

- All PULSE units are fully medicalised, with power and oxygen ports, integrated air management system and a flexible layout.

- PULSE’s lightweight, self-deploying structure allows it to rapidly deploy.

The PULSE Solution

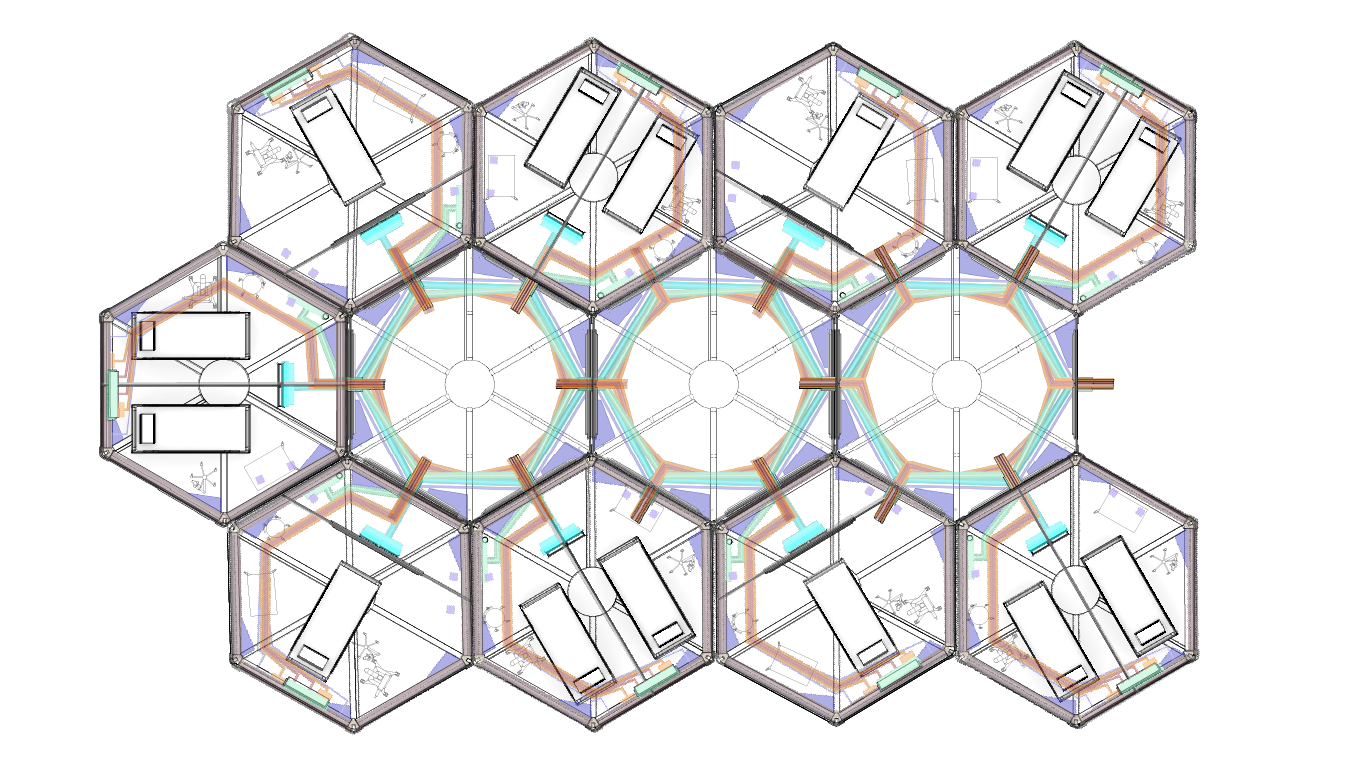

The PULSE Assembly

The PULSE unit is hexagonal in shape, allowing the aggregated PULSE assembly to tesselate with three degrees of freedom and no gaps. Hence, the PULSE assembly can expand both as radial clusters and linear rows, maximising space utilisation even in small or odd-shaped sites. This mode of aggregation is particularly well-suited to our industry partner’s preferred site layout of clusters of patient rooms arranged in rows, to facilitate easy monitoring of patients by staff whilst ensuring circulation efficiency. Adjusted to the existing NUH Covid-19 Annex site, the proposed PULSE assembly can house up to 24 patients, a 20% increase in the existing Annex’s capacity.

To efficiently provide single-pass airflow with rigorous air sanitation, the PULSE assembly relies on a central Air Handling Unit and Exhaust Sanitation Unit to supply all units with clean, chilled air and sterilise exhaust air for release into the environment. PULSE units connect securely to one another via an auto-locking mating port that also connects the flexible, valve-capped air ducts in the base, allowing PULSE units to be quickly added on or removed from the edges of the assembly seamlessly, without significantly interrupting airflow to the other units or incurring air leakage.

The PULSE Unit

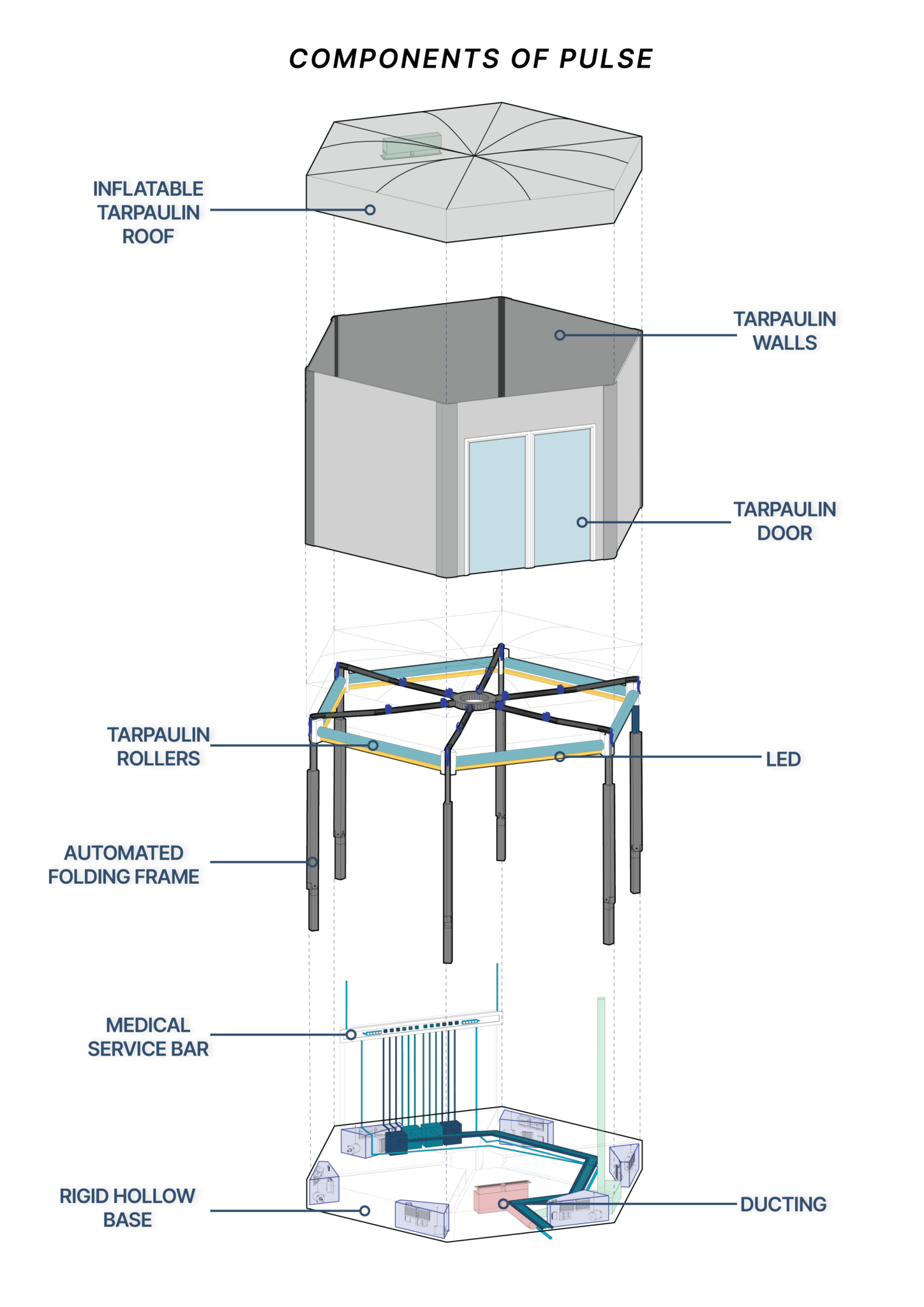

Overview of PULSE Components

Unit Configurations

To increase the flexibility of our proposed modular solution without overcomplicating setup logistics, two types of PULSE units were deviced: the walkway unit and the patient unit. The patient unit can also be quickly configured into two configurations to respond to the different medical requirement.

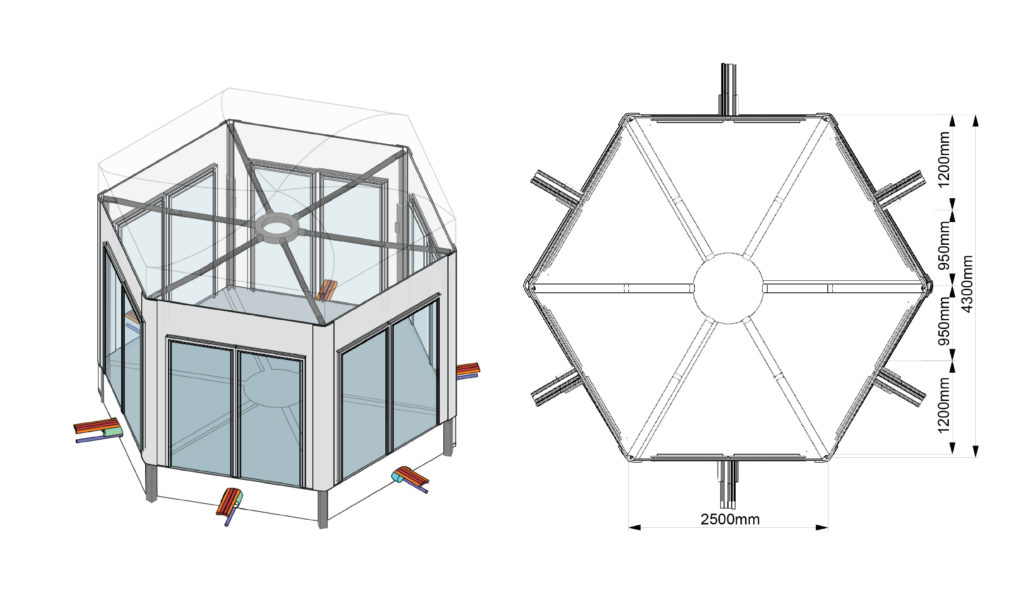

Patient Unit Configuration 1: High-Level Isolation Unit

The patient unit is a negative pressure capable unit that is internally reconfigurable between two different configurations.

The first configuration is the high-level isolation configuration, which is a single-occupancy, positively-pressured unit with an integrated negatively-pressured anteroom to act as an additional airtight barrier. This configuration is designed to contain highly infectious or immunocompromised patients who require stricter isolation and more available space within the patient room for high-intensity medical procedures. This configuration can also be used as a separate treatment area for high-intensity procedures like resuscitation.

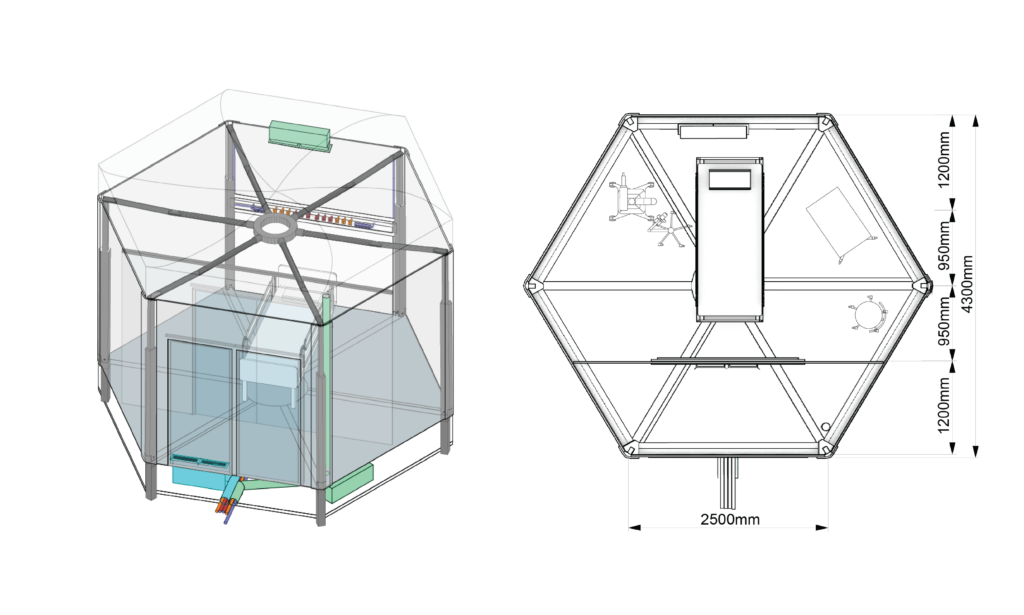

Patient Unit Configuration 2: Mass Containment Unit

Patient Unit Configuration 2: Mass Containment Unit

The second configuration is the mass containment configuration, which is a double-occupancy, negatively-pressured unit, with either patient isolated from the other. In this configuration, the attached walkway unit will function as a mass anteroom to all the patient units attached to it. This configuration is designed to cohort and isolate a larger volume of patients in the event of a highly transmissible but low-fatality disease outbreak, or an immediate need to increase the capacity of the PULSE assembly.

PULSE Deployment Mechanism

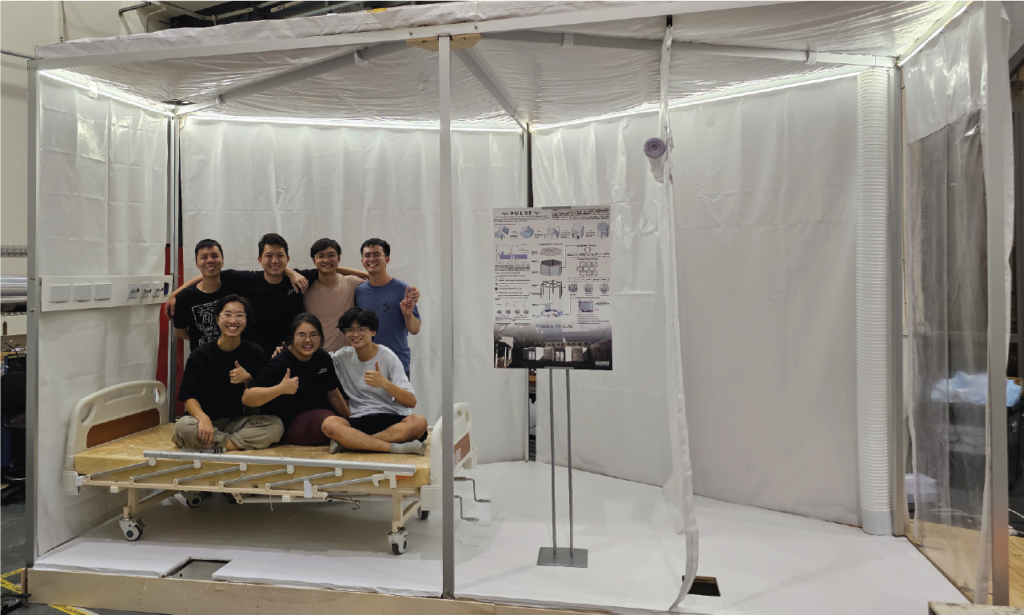

PULSE has a fully automated structure which can be rapidly deployed and stood down with minimal manpower. This is achieved through PULSE's innovative folding frame mechanism modelled on the action of a folding umbrella. As part of the testing and validation of our proposed solution, a 1:10 scale proof of concept prototype was designed and fabricated.

Overview of Deployment Process

1:10 Scale Mechanical Prototype

Each rhombus is balanced on 4 extendable legs to level the unit on uneven terrain and minimize heat transfer from the ground. Rhombuses would be levelled relative to a reference level using an IMU, and then the heights of all three rhombuses would be synchronized using a random walk algorithm to automate the process.

Each rhombus is balanced on 4 extendable legs to level the unit on uneven terrain and minimize heat transfer from the ground. Rhombuses would be levelled relative to a reference level using an IMU, and then the heights of all three rhombuses would be synchronized using a random walk algorithm to automate the process. PULSE EXPERIENCE

PULSE, as a conceptual solution, has proposed a novel approach to balancing the complex, opposing demands of a pandemic shelter response, mediating between speed of deployment and medical readiness, automated deployment and bulkiness, independence of each unit and systems efficiency.

Acknowledgements

The writers of this report would like to extend our sincere gratitude to our academic and industry mentors Professor Khoo Xiaojuan from the Engineering Product Development Pillar and Dr. Lenard Cheng from National University Hospital for their vital guidance, mentorship, and support in our project.

Our thanks as well to Dr Delfinn Tan, Professor Chong Keng Hua and Professor Javier G. Fernandez, whose incisive perspectives helped refine the direction of our project, as well as Mr. Liew Zhen Hui, Mr Goh Bean Ek, Mr. Andy Lim, and Mr. Ken Thiang from the SUTD Fabrication Laboratory staff, whose technical expertise has provided vital support for our project.