Own Green Agripod

Harnessing Sunlight for Local Food Security

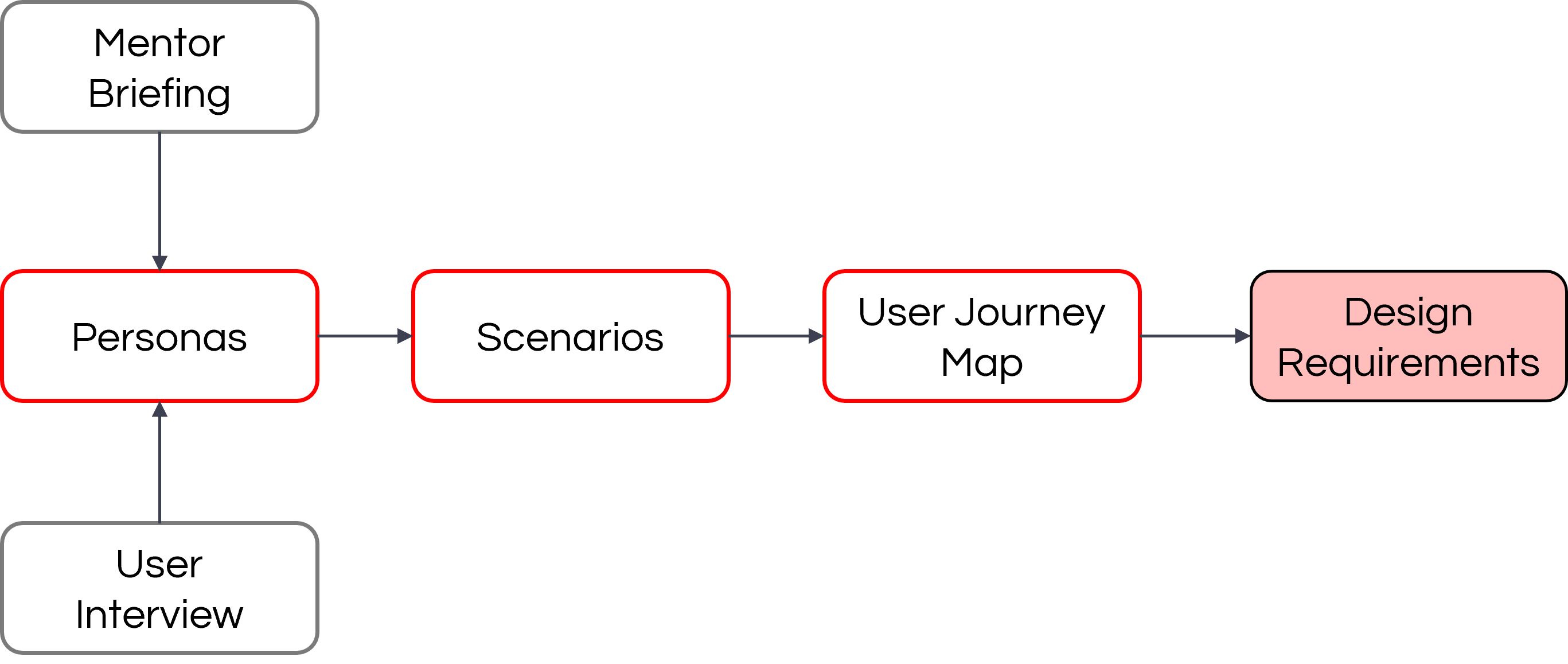

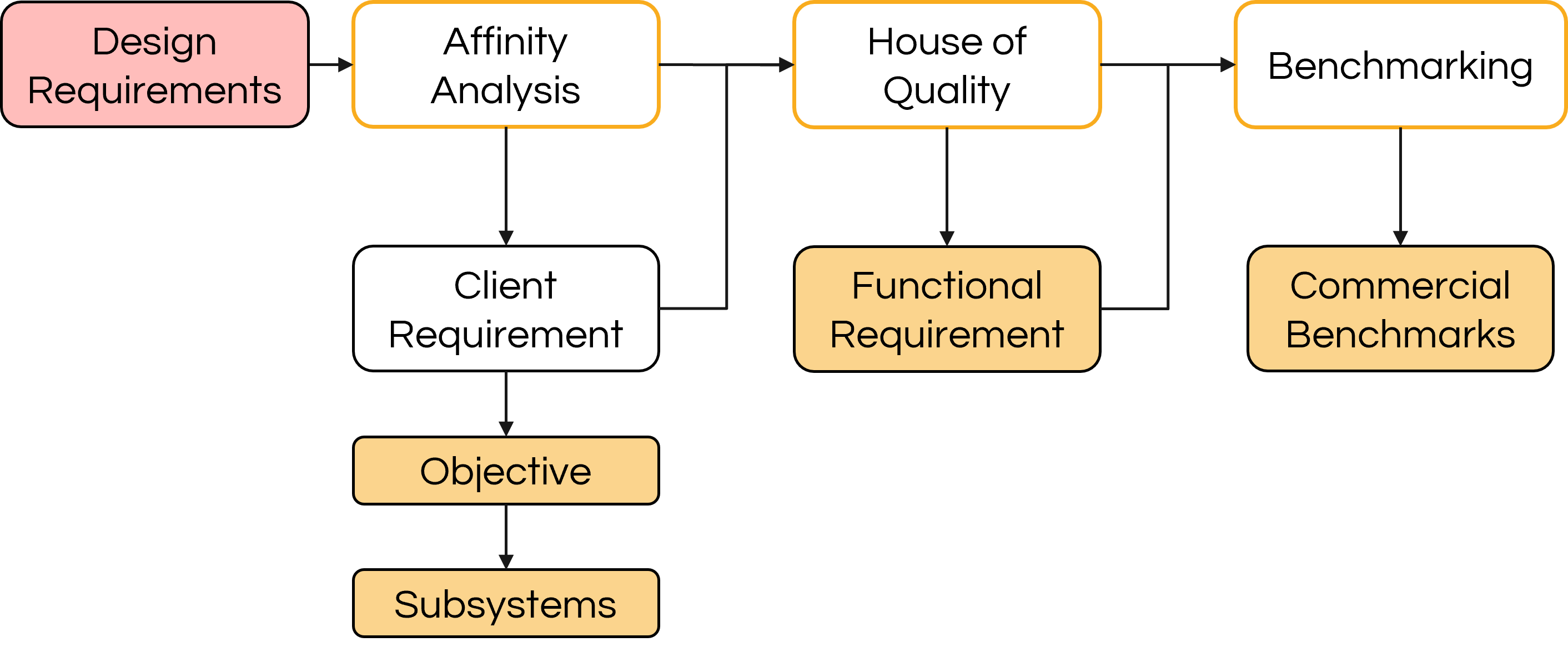

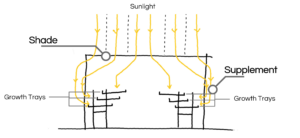

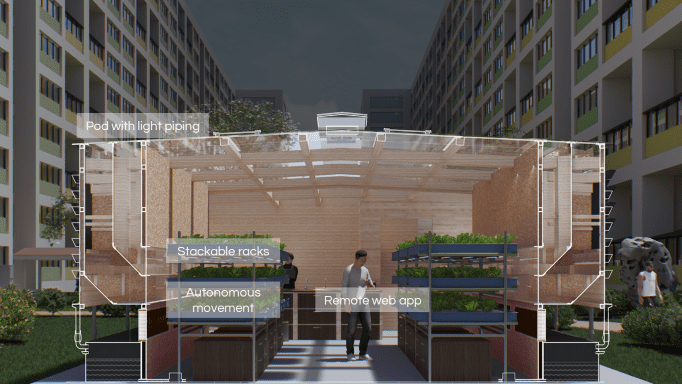

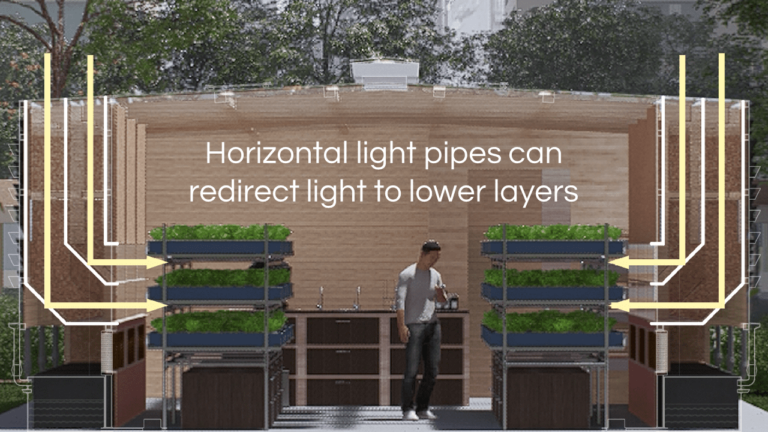

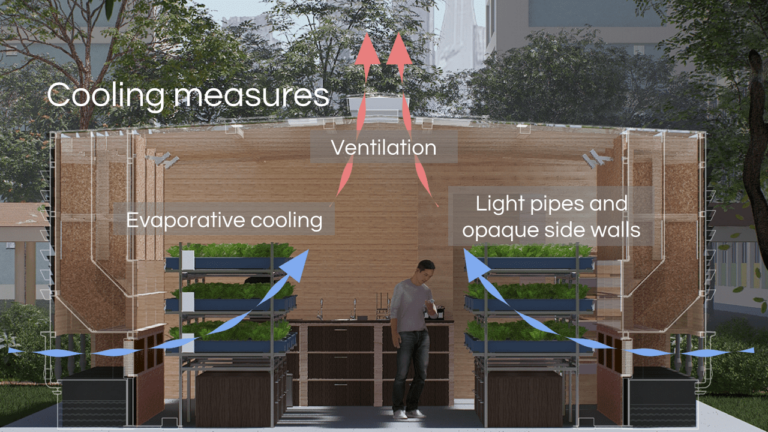

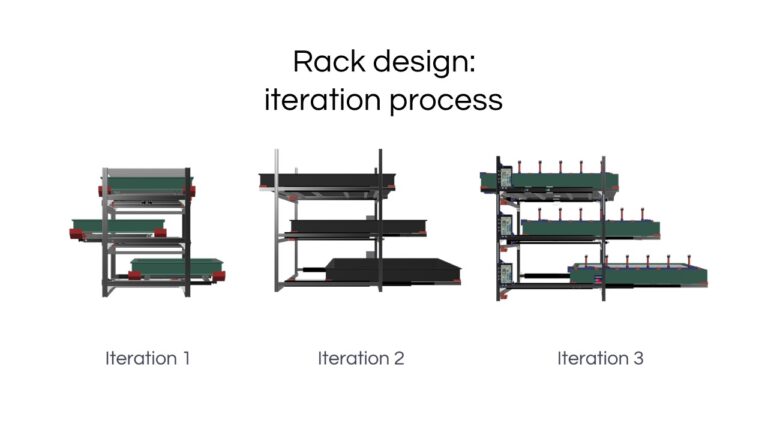

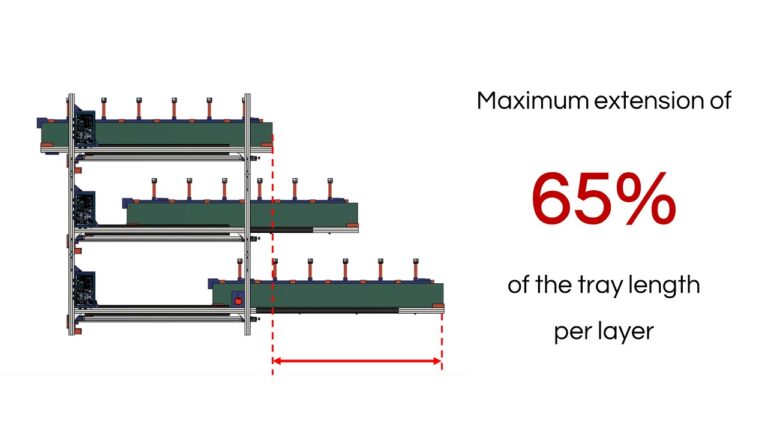

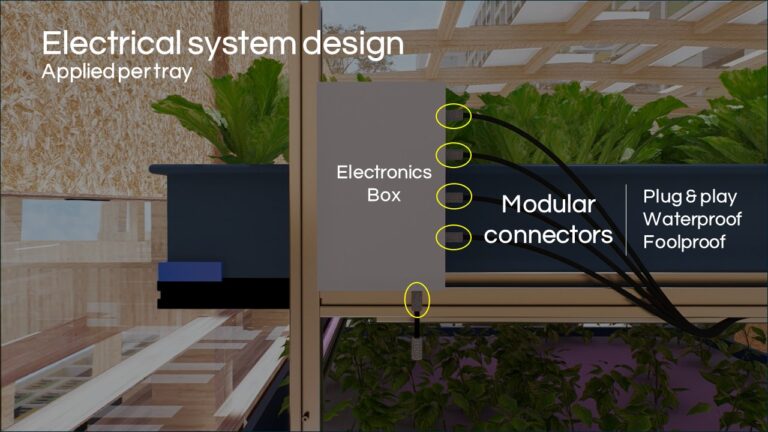

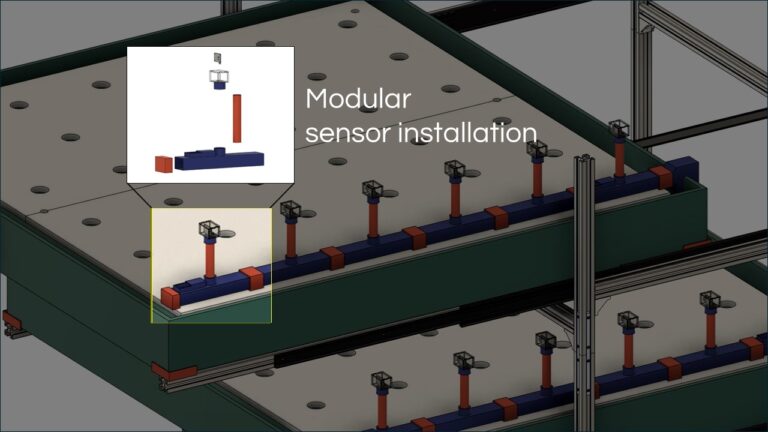

A climate-reactive, modular envelope containing automated, modular hydroponic racks, controlled and monitored by a remote management web application.

Introducing Own Green Agripod

The Singaporean government launched the ambitious “30 by 30” initiative with aims to produce 30% of the nation’s nutritional requirements locally by 2030 to ensure the nation’s food security. However, achieving this goal is challenging due to Singapore’s limited land space, with less than 1% allocated for farming. Controlled Environment Agriculture (CEA) pods offer an urban farming alternative which optimises land use. Collaborating with WAVE Design Consultants, Own Green Agripod introduces a comprehensive CEA system featuring a climate-reactive and modular envelope with automated hydroponic racks. These racks, controlled via a remote management web app, responds to daylight and prevents overheating. These features make CEA pods suitable for tropical climates while reducing operational costs, hence improving system viability in Singapore.

Team members

Justin Eng Hee Yang (ASD), Jade Megan Chan (EPD), Quek Shao Min Charissa (EPD), Poh Boon Pin (EPD), Christopher Lye Sze Kian (CSD), Peng Jing Ming Jason (CSD), Wee Chun Hui (CSD)

Instructors:

-

Thomas Schroepfer

-

Geraldine Quek Cai Ting

Writing Instructors:

-

Susan Wong