Background

The Nanotechnology industry uses special patterned moulds to produce extremely small, valuable devices and components. These devices are used in microchip, optics, and biotechnology applications.

Enlitho uses the powerful and precise Electron Beam Lithography (EBL) process to manufacture the aforementioned moulds. However, efficient mass manufacture of these moulds remains an industry challenge.

Applications

Microchips (GPUs and CPUs)

Optical Microlens (VR/AR Lens, Holograms)

Biotech Microfluidics (Lab-on-a-chip)

Industry Pain Points

Expensive

The immense cost of traditional nano-fabrication tools make them inaccessible to smaller labs and start-ups.

Slow

Traditional processes like Electron Beam Lithography (EBL) tend to be very slow, hindering mass production capabilities.

Manual

Manual imprinting and inspection are time-consuming and labour-intensive, as well as less effective at the nano-scale.

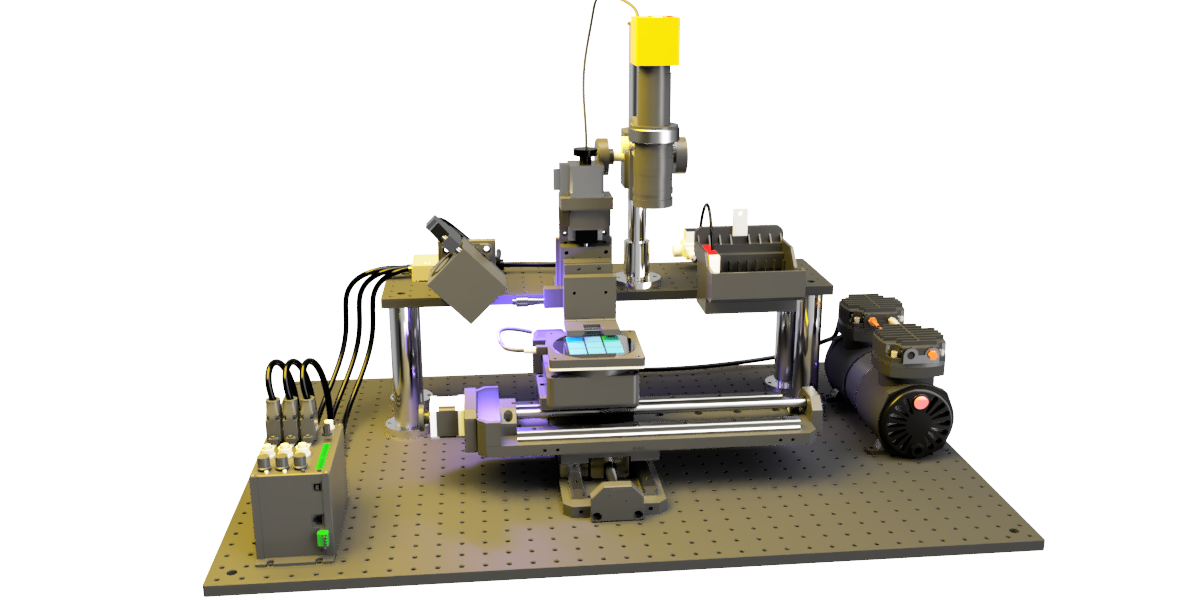

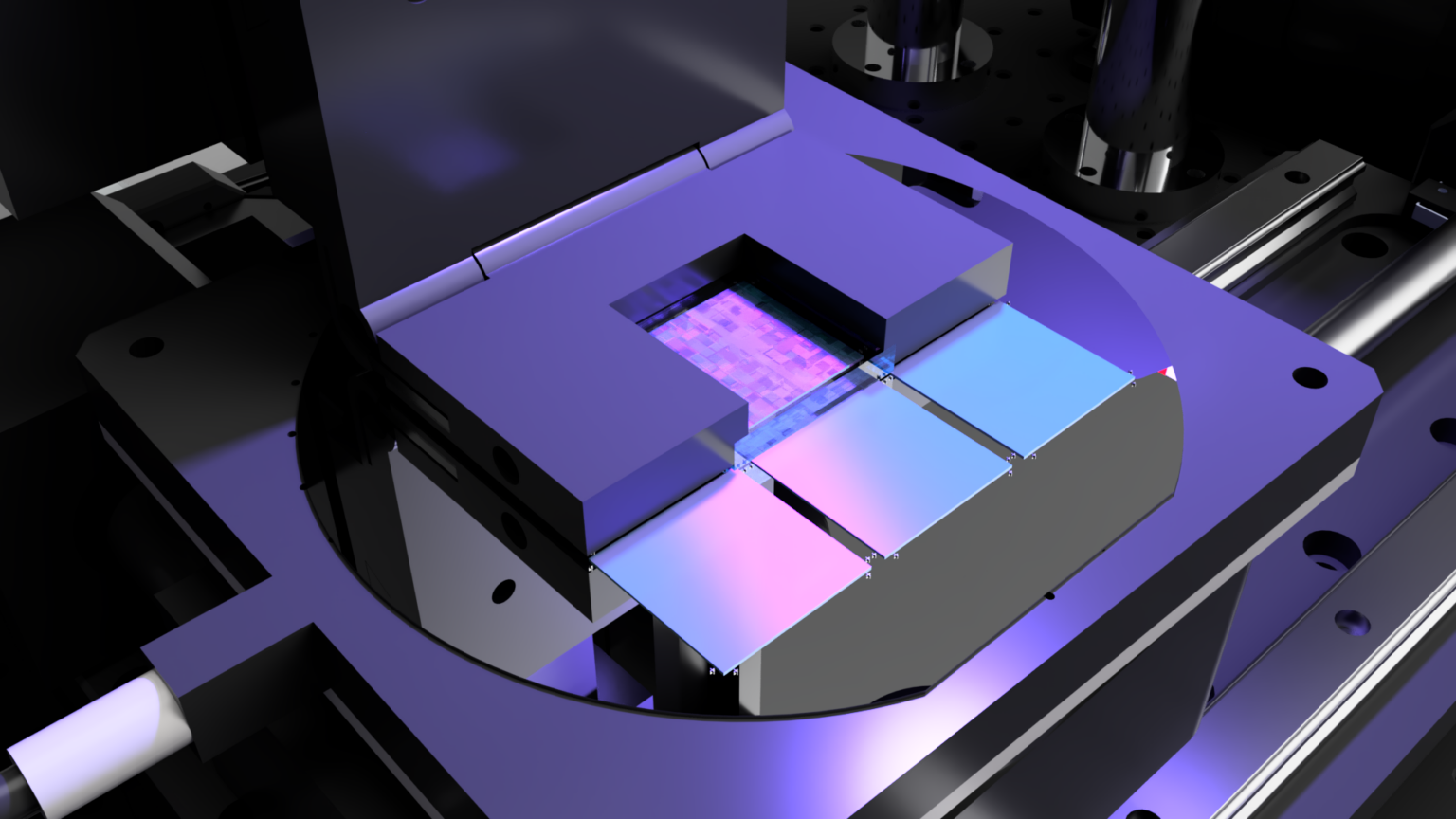

Solution: A one-stop Step & Repeat Nanoimprint Lithography Machine

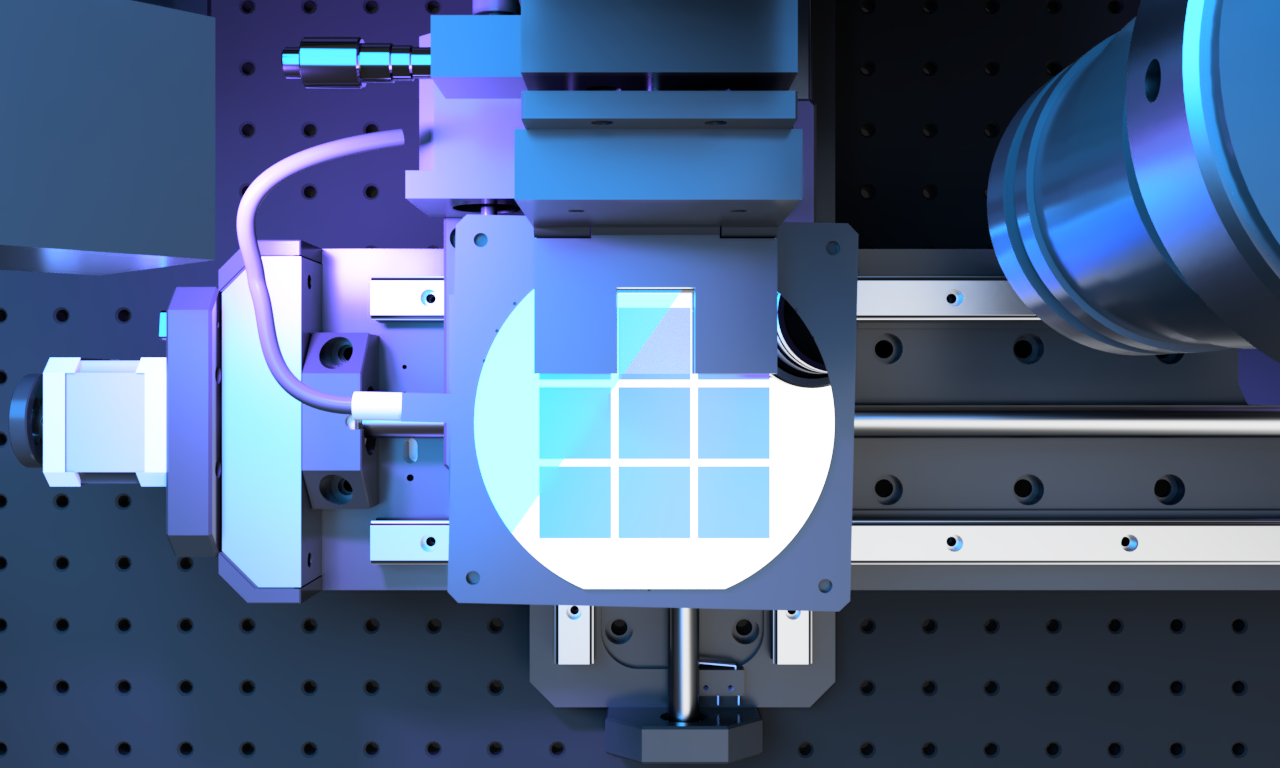

Step & Repeat Nanoimprint Lithography is a highly scalable technique in nanotechnology manufacturing for duplicating intricate patterns onto moulds and minuscule devices.

Features and subsystems

Fast, Reliable and Scalable Imprinting

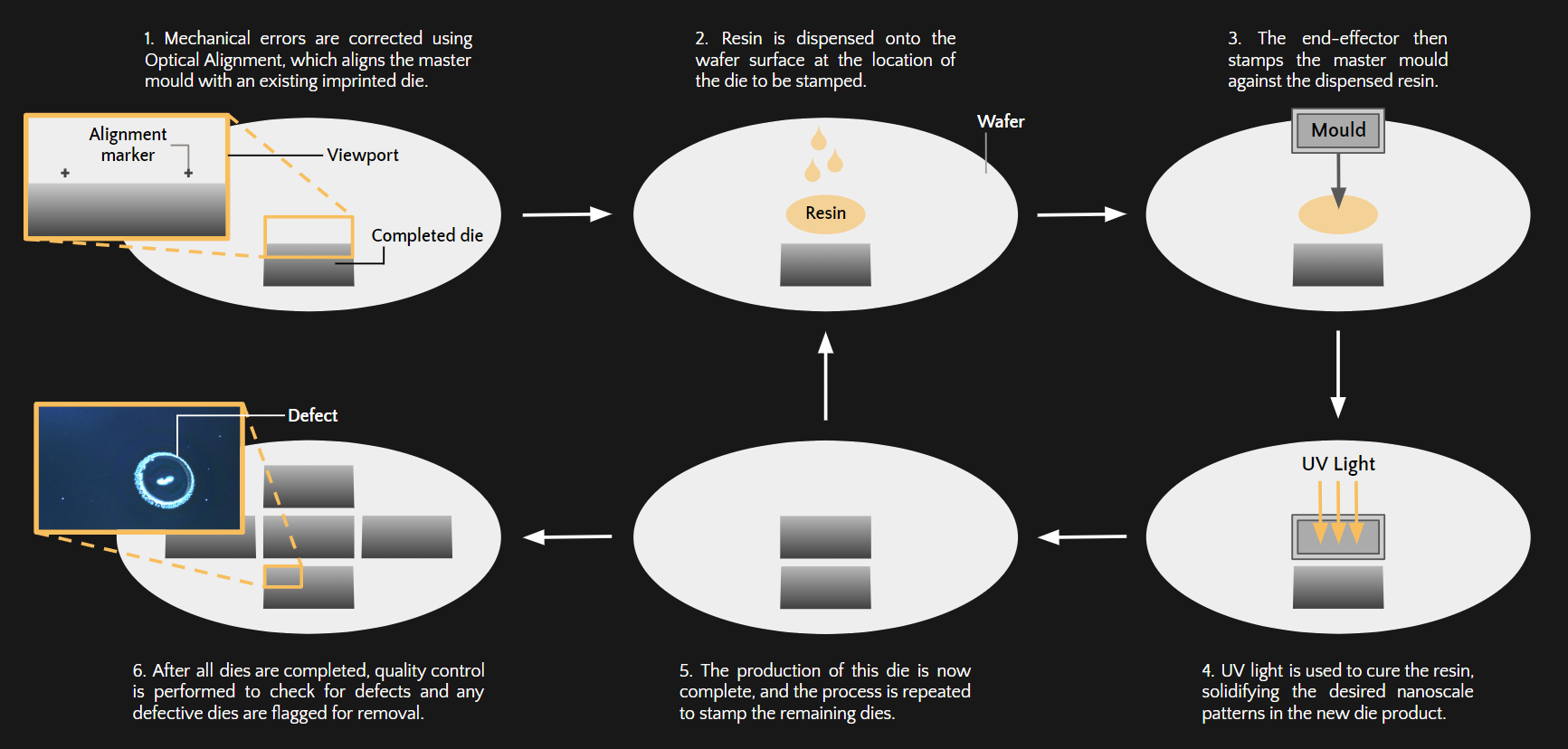

The imprinting subsystem covers every crucial step from dispensing resin to stamping the master mould, creating new moulds. By fully automating such machine performance, the nanoimprint lithography process is sped up by displacing numerous time-consuming, manual practices.

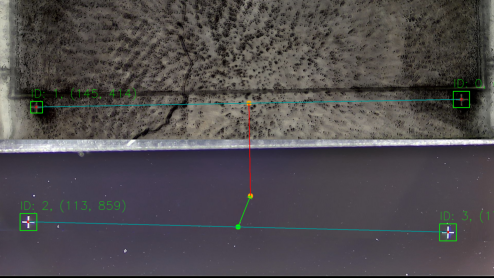

Automatic Alignment using Computer Vision

Computer Vision is utilised to prevent misalignment by automatically correct mechanical errors using the alignment markers (AMs) of each die.

Automated Quality Control and Defect Detection

Our Computer Vision model performs automated defect detection to identify defective dies to be removed. This fast and automated approach reduces cost and manpower requirements.

The Process

Added value

Inexpensive

200x Lower initial cost:

Our compact tabletop design reduces the high expenses associated with EBL, offering an affordable solution while maintaining high-quality results.

Fast and Robust

5x Increase in alignment speed:

By displacing manual tasks in the nanoimprinting process with precision machinery, throughput and quality are greatly increased.

Automated

No human intervention required:

The use of computer vision and AI for alignment and quality control eliminates the need for human intervention.