Prototype Gallery

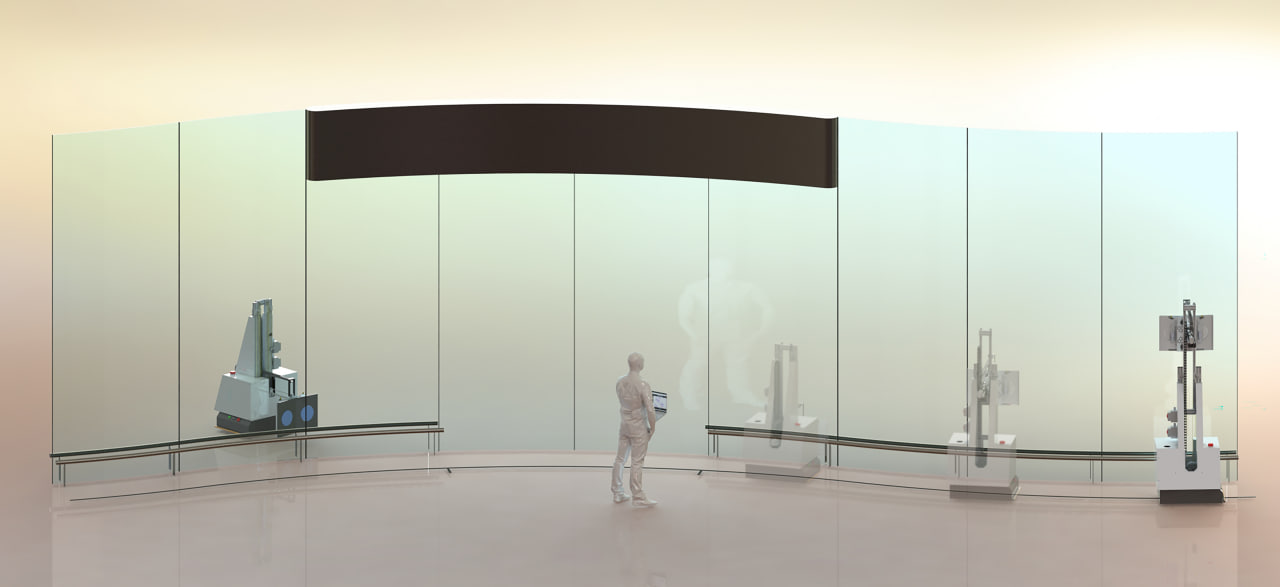

An innovative and portable autonomous robot for large-scale cleaning of curved glass barriers, with a web application for real-time monitoring and targeted cleaning control.

Yang Hui Ying

Grace Kong

Bernard Tan

With a length of around 200m and a height of around 4m, the glass barriers in the arrival halls are the first things tourists and returning Singaporeans see when they enter Singapore. As such, these barriers’ cleanliness is a main priority, having cleaners clean them regularly. According to an airport cleaner we interviewed, these barriers are manually cleaned daily in the morning. Cleaning is done with a moist microfibre cloth and without ladders to reach higher heights. As CAG looks towards bringing automation into Changi Airport, one of the main areas it is exploring is the automation of cleaning, reducing the workload required to maintain the desired level of cleanliness.

“How might we design an efficient and portable robot for large-scale automated cleaning of glass panels of varying curvatures in the arrival halls at Changi Airport?”

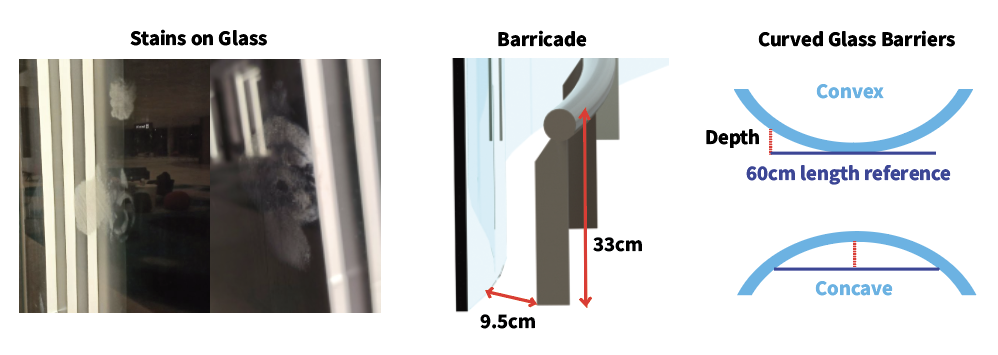

A site analysis was done at the Terminal 2 arrival hall, where three main challenges were identified for cleaning automation. Firstly, we noted that our robot must be able to reach 2m height as it is a human-reachable length and is more prone to stains such as lipstick marks and fingerprints. Secondly, there is a short metal barricade, which we will need to overcome to clean the lower edge of the glass barrier. Thirdly, we quantified the depth of the curve to have a maximum of 2cm depth using a 60cm length reference, which we have to account for in our robot’s end effector design.

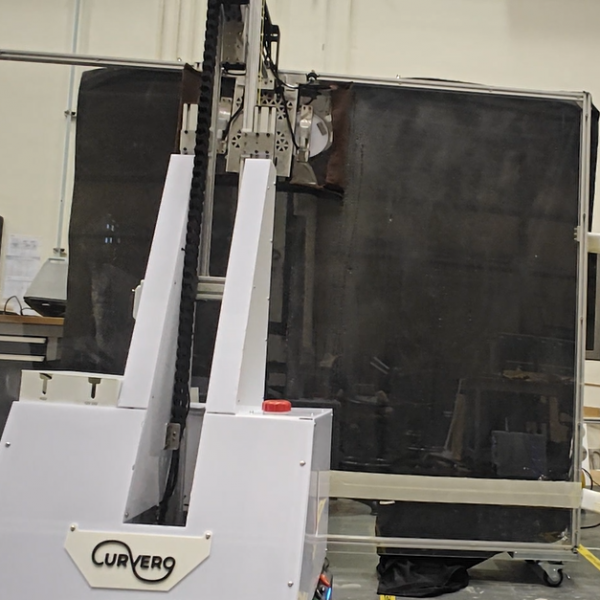

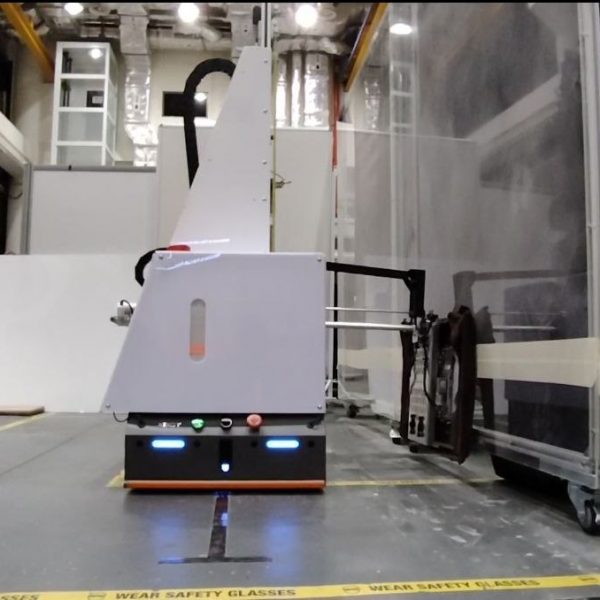

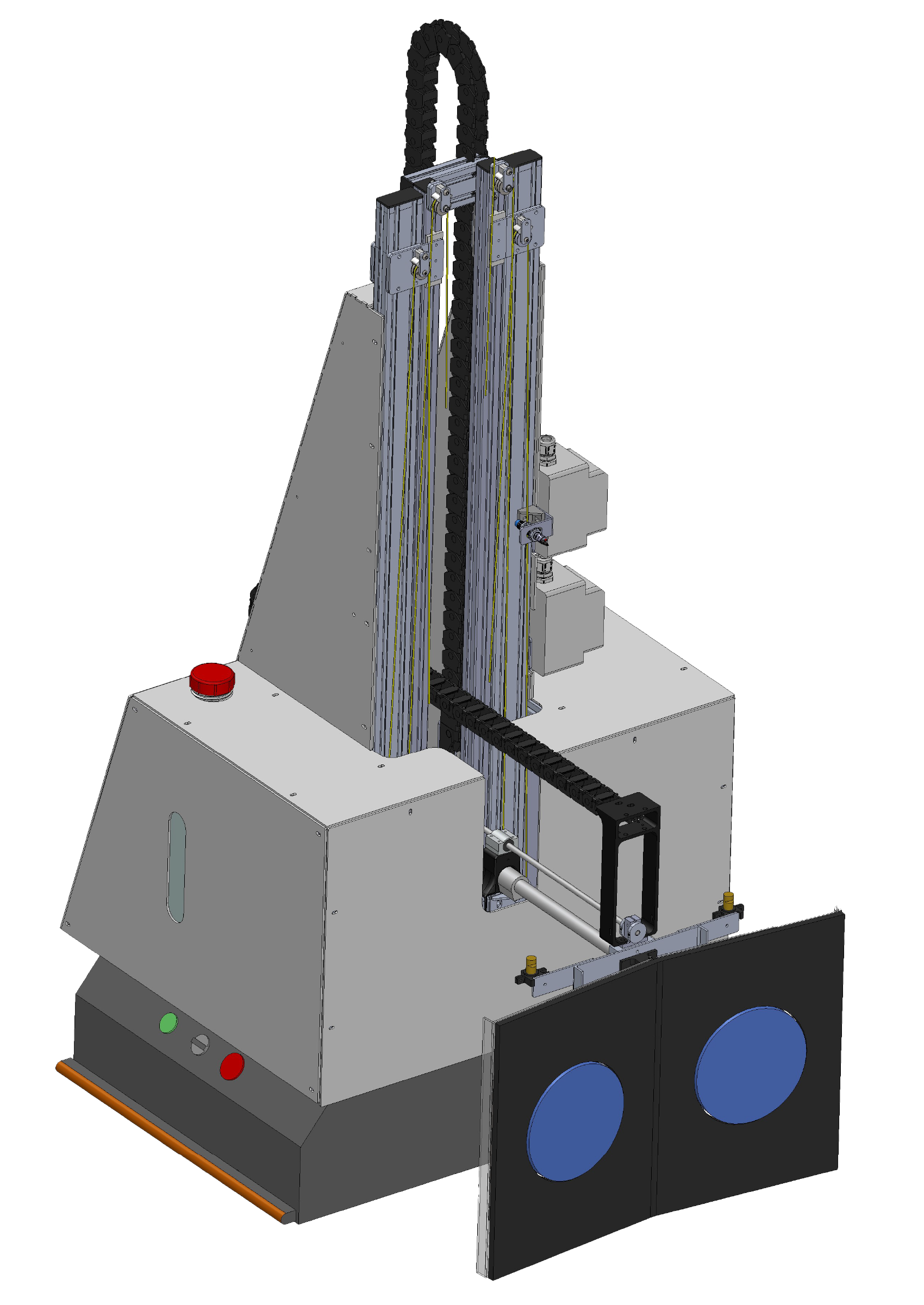

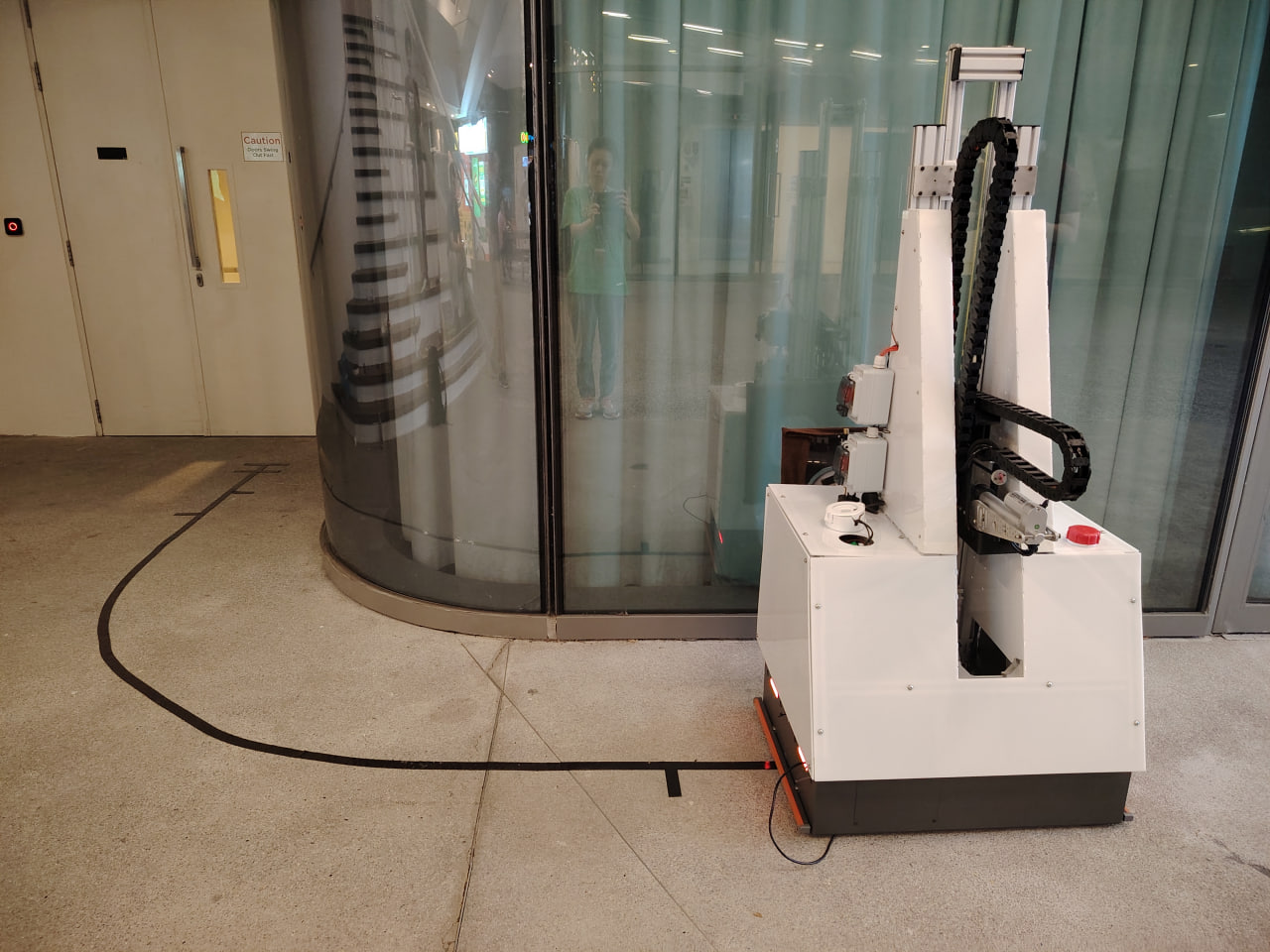

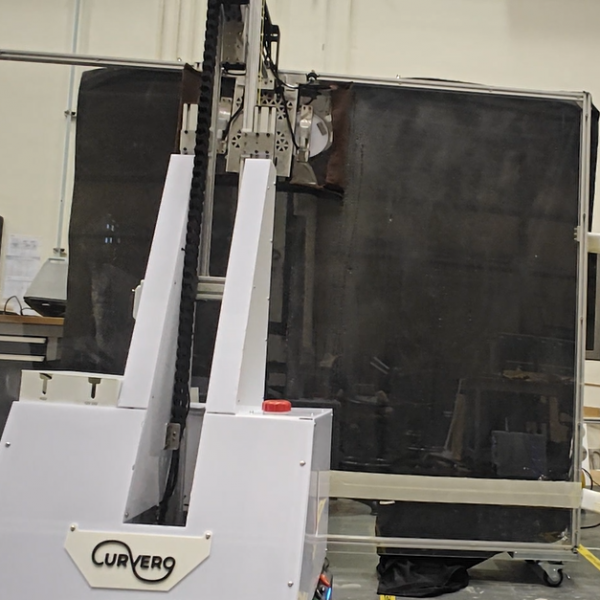

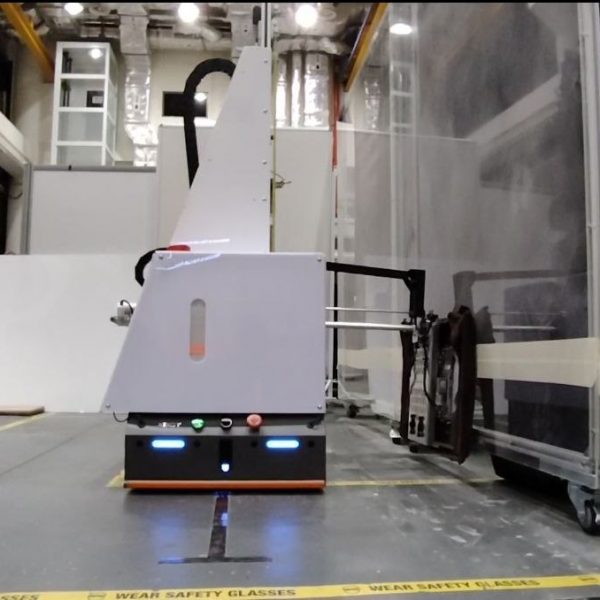

Curvero uses a commercial AGV (XBOT-100) as a base to move our lifting and cleaning mechanisms. The lifting mechanism consists of a cascade lift, when collapsed, stands at a height of 1.51m. It extends to allow the brush head to be positioned anywhere from the ground to a height of 2m. The cleaning mechanism consists of a linear actuator and brush head that provides sufficient force and area to clean the glass barriers. Furthermore the size of the brush head is constrained to the space between the metal barricades and glass barriers while still being able to conform to the curvature of the barriers.

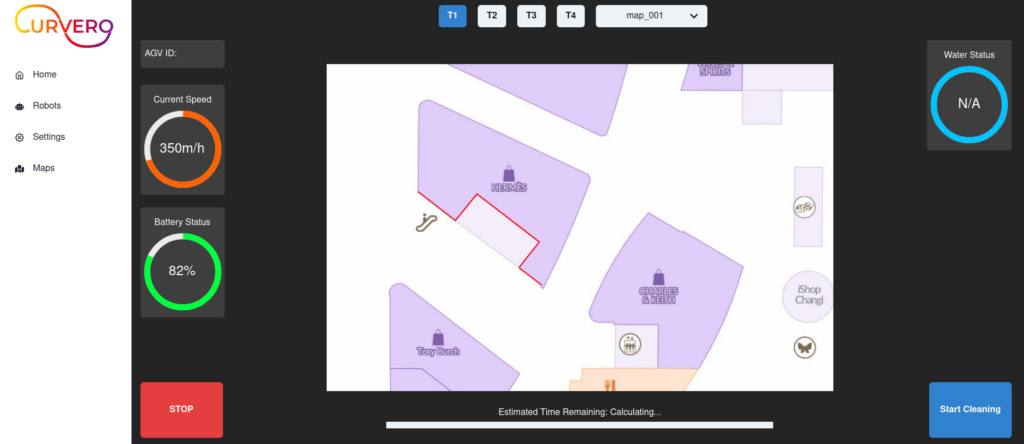

ROS2 is used to monitor the robot, allowing for ease of use and control as well as providing a layer of safety along with other features mentioned more in the later sections.

With magnetic tape to guide the robot, Curvero uses a brush head specifically designed to match the curvature of the surface being cleaned. With a battery capacity of 1416 Wh, the robot is designed to operate for 2 hrs before a recharge is required, allowing for a significant portion of the cleaning to be done automatically.

Emergency stop buttons on the robot allows for power to be cut to the lifting mechanism, the linear actuator as well as the robot, while still providing power to the PC onboard. There is, additionally, a software emergency stop button, providing multiple ways for the robot to isolate certain systems should there be an emergency. Furthermore, there are multiple other electrical safety features should there be an incident, allowing for safe disengage for the subsystems in the robot.

With the robot requiring multiple signals and processes, we split the processing work onto 2 different Arduinos Nano 33 BLE, with a Jetson Orin Nano working as the main CPU in place of a laptop. With ROS2 and the Curvero web application, cleaners at Changi Airport will be able to remotely control the robot from the graphics user interface (GUI). Furthermore, the Arduinos are taking information from the various sensors to monitor the robot’s actions, ensuring that each subsystem is operating in accordance within operating procedure. The diagram shows the interaction between our components and how data is transmitted in the system.

In this section, we will be going through each individual subsystem and the control system that is used to ensure effective and safe operation. Curvero was built with safety in mind as it is tasked to deal with a space that encounters high traffic flow.

Meet Curvero’s Lifting Mechanism—a high-speed, high-precision vertical actuator designed to elevate and position heavy components with power, control, and reliability.

a robust cascade lift system engineered to elevate a 15 kg payload (the weight of its own components, the Y-axis Actuation Mechanism and Brush Head) to a height of 2 meters in just 5 seconds.

Precision is built into every movement. Encoders, proximity sensors, and limit switches work in perfect sync to provide flawless height control. Real-time positional data feeds into a closed-loop feedback system, enabling smooth, repeatable lifting motions—while automated deceleration enabled by a proximity sensor eliminates abrupt stops, protecting the payload.

Power doesn’t have to be loud. Curvero’s cascade lift runs on a silent electric motor paired with POM (polyoxymethylene) sliders—eliminating the clatter and vibration commonly associated with traditional chain-driven lifts.

Safety is built in at every level. Curvero’s lift features a physical e-stop and a software-based e-stop accessible via the web app—so you’re always in control, even in unexpected situations.

Self-lubricating POM sliders and high-strength synthetic Dyneema strings replace traditional components like steel rollers and metal chains that require constant care. The result? A low-maintenance, worry-free system that keeps on performing.

Main Contributor:

Meet Curvero’s Y-axis Actuation— the system maintains consistent brush pressure towards the glass surface, compensating for the robot base movement errors (± 15 cm) during large-scale cleaning. Powered by real-time force feedback, current monitoring, and a smart control system.

PD controller adjusts linear actuator to apply steady force against the glass, using real-time FSR input.

Force Sensing Resistor (SEN-0047) detects glass contact pressure. Enhanced with a 3D-printed compliant force mechanism for better sensitivity and range.

ACS712 sensor monitors linear actuator current to detect brush contact and prevent overcurrent. This accelerates the approach phase, reducing delay in reaching the glass surface.

Connects Arduino Nano, sensors, motor drivers, and a fan for clean, reliable wiring and easy maintenance.

Features auto/manual modes, deep-cleaning motor control, force calibration, active cooling, and state machine logic—refined with Kalman filtering.

Main Contributor:

Meet Curvero’s Brush Head Mechanism — The Brush Head is designed to mechanically conform with glass barriers of various curvatures within the arrival halls. It is reliant on the Y-axis actuation system’s force control algorithm to allow for additional compliance with the glass.

In order to clean the area behind the metal barricade, the Brush Head adopts a flanged design to minimise material deflection without the need of using a thicker material. This allows the Brush Head to be compact.

The spring mechanisms allows for mechanical compliance for convex, concave and straight glass barriers of a maximum of 3cm depth (60cm length reference).

The brush head consists of of 2 high torque (Stall torque: 6.4kg.cm) 12V JGY-370 DC motors to overcome torsional friction to rotate microfibre brush pads to clean tougher stains of the glass. These motors are controlled by a motor driver board which allows for programmable speed and direction control. The brush head is tested to be able to remove cornstarch slurry.

In order to provide effective cleaning, the Brush Head comes with 2 nozzles attached to a water supply system. The nozzles allow for a flat and wide stream of water upon command to be sprayed on to the glass. This allows the Brush Head to be moist and for cleaning to be more effective.

Main Contributors:

The web application provides an intuitive interface for monitoring and controlling the robot. Users can track key metrics of the robot, including battery status, current speed and water level, while also viewing its real-time location on a dynamic map. A progress bar is included to keep users informed of the estimated time remaining for the cleaning process. Additionally, users can issue simple commands to start cleaning or stop all movements with ease. The platform also supports multiple map uploads and allows seamless switching between airport terminals for efficient management.

The glass cleaning robot employs ROS2 architecture to coordinate its autonomous operations through a sophisticated state machine framework. Following magnetic tape for navigation, the robot progresses through clearly defined states from initialization and standby to complete cleaning cycles, with Arduino microcontrollers precisely managing the lifter’s vertical movement and the actuator’s pressure against glass surfaces. The robot demonstrates adaptive behavior by automatically responding to obstacles, managing transitions between panels, and providing real-time progress tracking—all within a modular design that facilitates future enhancements.

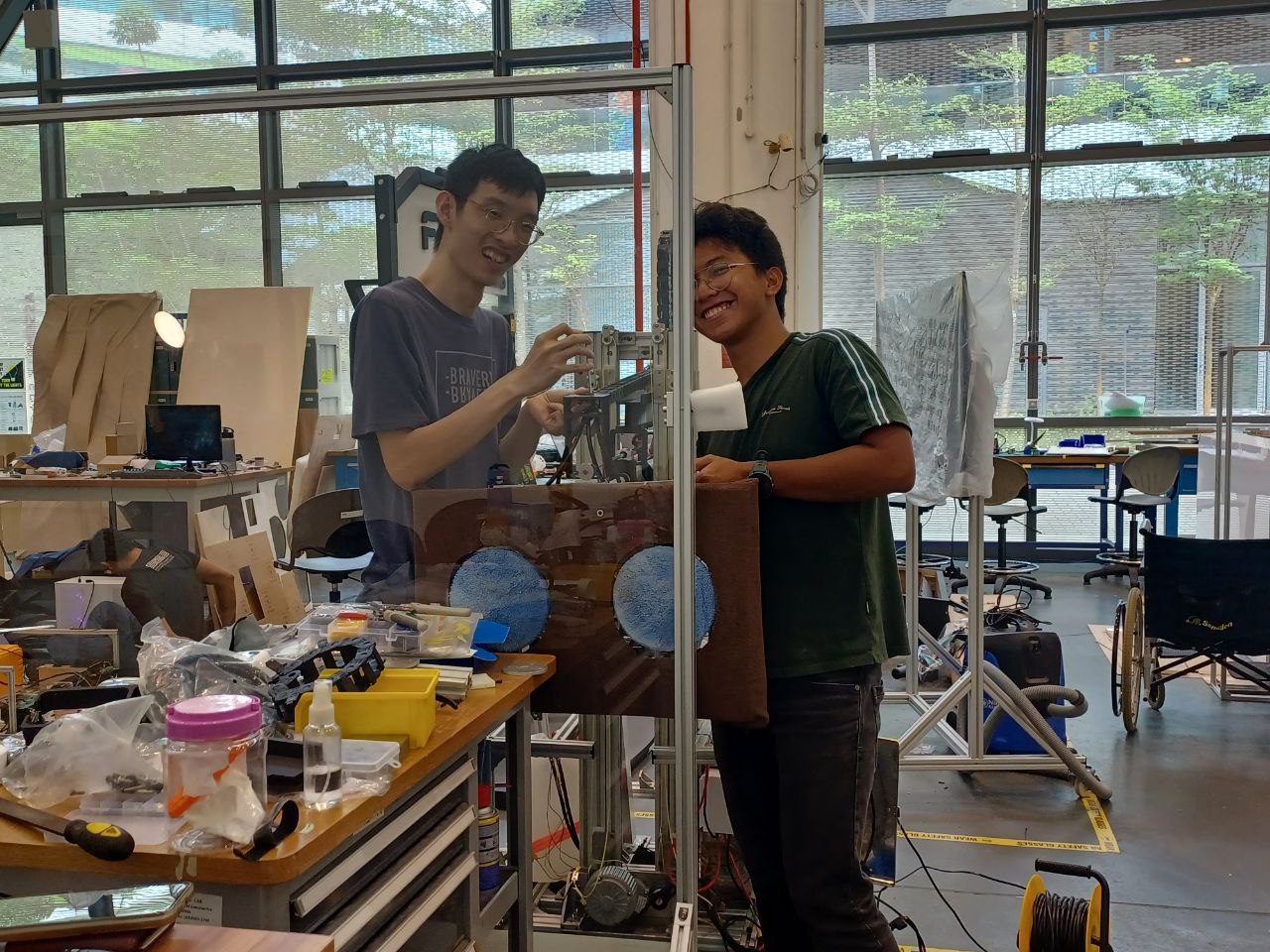

Team Curvero would like to thank our Capstone instructors: Professor Yang Hui Ying and Lecturer Mahamarakkalage Dileepa Yasas Fernado for their valuable advice which were pivotal to Curvero’s success. We would also like to thank the SUTD FabLab, CWR and Capstone office for their support.

The team would like to thank our Industry mentor, Shu Peng, for his valuable guidance and help in securing resources and space for Curvero.

Vote for our project at the exhibition! Your support is vital in recognizing our creativity. Join us in celebrating innovation and contributing to our success. Thank you for being part of our journey!

At Singapore University of Technology and Design (SUTD), we believe that the power of design roots from the understanding of human experiences and needs, to create for innovation that enhances and transforms the way we live. This is why we develop a multi-disciplinary curriculum delivered v ia a hands-on, collaborative learning pedagogy and environment that concludes in a Capstone project.

The Capstone project is a collaboration between companies and senior-year students. Students of different majors come together to work in teams and contribute their technology and design expertise to solve real-world challenges faced by companies. The Capstone project will culminate with a design showcase, unveiling the innovative solutions from the graduating cohort.

The Capstone Design Showcase is held annually to celebrate the success of our graduating students and their enthralling multi-disciplinary projects they have developed.