WHAT is our project about?

NewNails creates press on nails with high-precision, customised fit like never seen before. Press on nails meet state of the art technology, using the latest Artificial Intelligence tools (AI), 3D scanning and 3D printing.

The busy modern woman no longer has to choose between beauty and efficiency by spending hours in salons for traditional manicures. NewNails gives her the best of both worlds; all it takes is a swift, one-time scan before she is once again on the move.

WHY are we doing this?

Even the busiest modern woman who is constantly on the move dreams to have beautiful, glamourorus nails.

Traditional salon manicures can take hours each time. Press on nails are fast, but often fits poorly as nail shapes and curavture are unique from person to person. NewNails solves this with well-fitted, durable, beautiful nails, which consumes minimal time of our customers.

Scanning team designed and tested a stable, automated setup using a high-precision 3D scanner and custom jig to capture accurate nail data. Their setup ensured consistent scans with minimal user effort, laying the foundation for precise nail modeling.

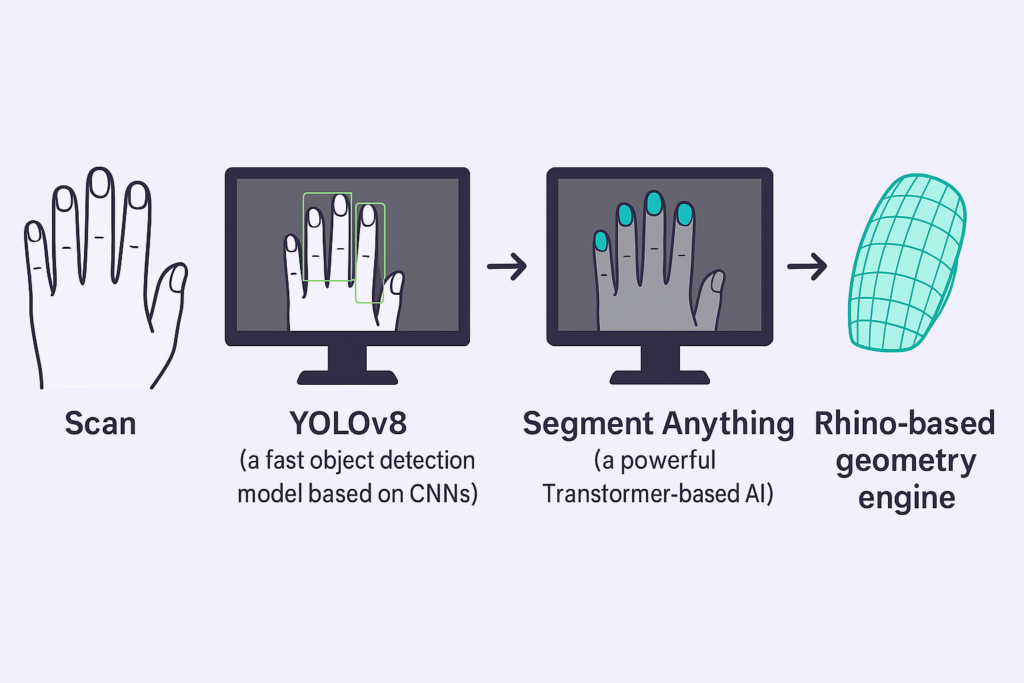

Processing team handled segmentation and model generation using AI tools like YOLOv8 and Segment Anything. They turned raw scan data into clean 3D nail shapes, refining the geometry to ensure a snug fit and smooth surface ready for printing.

Printing team tested various 3D printing methods and finalized an SLA workflow for high-quality, durable nails. They optimized resin use, layout, and post-processing steps to produce detailed nails efficiently and at scale.

In Term 7, the focus was on testing and exploration. The team tried various scanners, including iPhone and industrial options, but results were unstable or imprecise. A basic jig concept was introduced, but automation hadn’t started. Most of the model segmentation and 3D processing were done manually, and printing was outsourced, resulting in issues with nail fit, shape, and surface quality.

By Term 8, major improvements were made. The scanning process was automated with a motorized jig using Arduino, solving stability and thumb scanning issues. Auto-segmentation with YOLOv8 and SAM was introduced, along with auto-preprocessing scripts to generate nail extensions. Printing moved in-house with LCD resin printers, improving speed, control, and quality. User testing was also added, helping to refine the nail design and scanning experience based on real feedback.

Scanning group selected a high-precision handheld scanner and built an automated track system with Arduino control to improve scanning accuracy and stability. They refined hand placement and motion to ensure clean, complete nail scans for further processing.

Pre-processing group developed an automated segmentation and modeling pipeline using YOLOv8 and Rhino. They cleaned the scanned data, generated nail shapes with extension, and produced print-ready 3D models with customized fit and design.

Printing group tested multiple methods and finalized resin printing with improved manual and automated pre-processing. They optimized for clarity, shape, and durability, using both outsourced and in-house LCD printers for better control and faster turnaround.

We use a state-of-the-art handheld 3D scanner with 0.02mm precision (less than a hair strand!) to capture the tiniest details of your natural nails.

To make sure every scan is smooth and consistent, a custom-built automated cantilever system guides the scanner along a fixed arc route, while your hand rests in place.

This setup eliminates human error and ensures every scan is clean, precise, and ready for perfect-fitting nails—every time.

After scanning, the design process is powered by cutting-edge AI.

We use YOLOv8 (a fast object detection model based on CNNs) to locate each nail in the scan. Then, Segment Anything (a powerful Transformer-based AI) outlines the nail shapes with pixel-level accuracy.

Finally, our Rhino-based geometry engine runs automated design algorithms that generate a 3D nail extension perfectly matched to your natural nail size and shape—ready to be 3D printed just for you.

Looking ahead, the project aims to expand through partnerships with professional nail salons to offer a complete end-to-end service. After the custom press-on nails are 3D printed, they can be handed off to salon artists for painting, finishing, and bespoke design work—adding a personalized, artistic touch to each set.

This collaboration bridges cutting-edge digital fabrication with traditional nail artistry, allowing salons to offer a premium, tech-enhanced experience. As part of this vision, the full scanning and customization setup—including the 3D scanner, automated cantilever, and software pipeline—can be installed directly in salon retail spaces, enabling customers to get scanned and fitted on-site. This deployment model brings convenience to users while creating new service and revenue opportunities for salon partners.