As electric aircraft take to the skies, one component stands out as mission-critical: the battery.

Batteries are the heart of electric aviation — but they degrade with constant use. Without smart management, this degradation can impact performance, cost, and sustainability.

With continuous use, batteries can lose up to 45% of their capacity within a year, reducing flight range and driving up operational costs.

Degraded batteries also demand more frequent maintenance and replacements, leading to increased downtime and expenses for airlines. On top of that, the environmental impact grows as faster degradation accelerates the need for new batteries, which rely on resource-intensive materials.

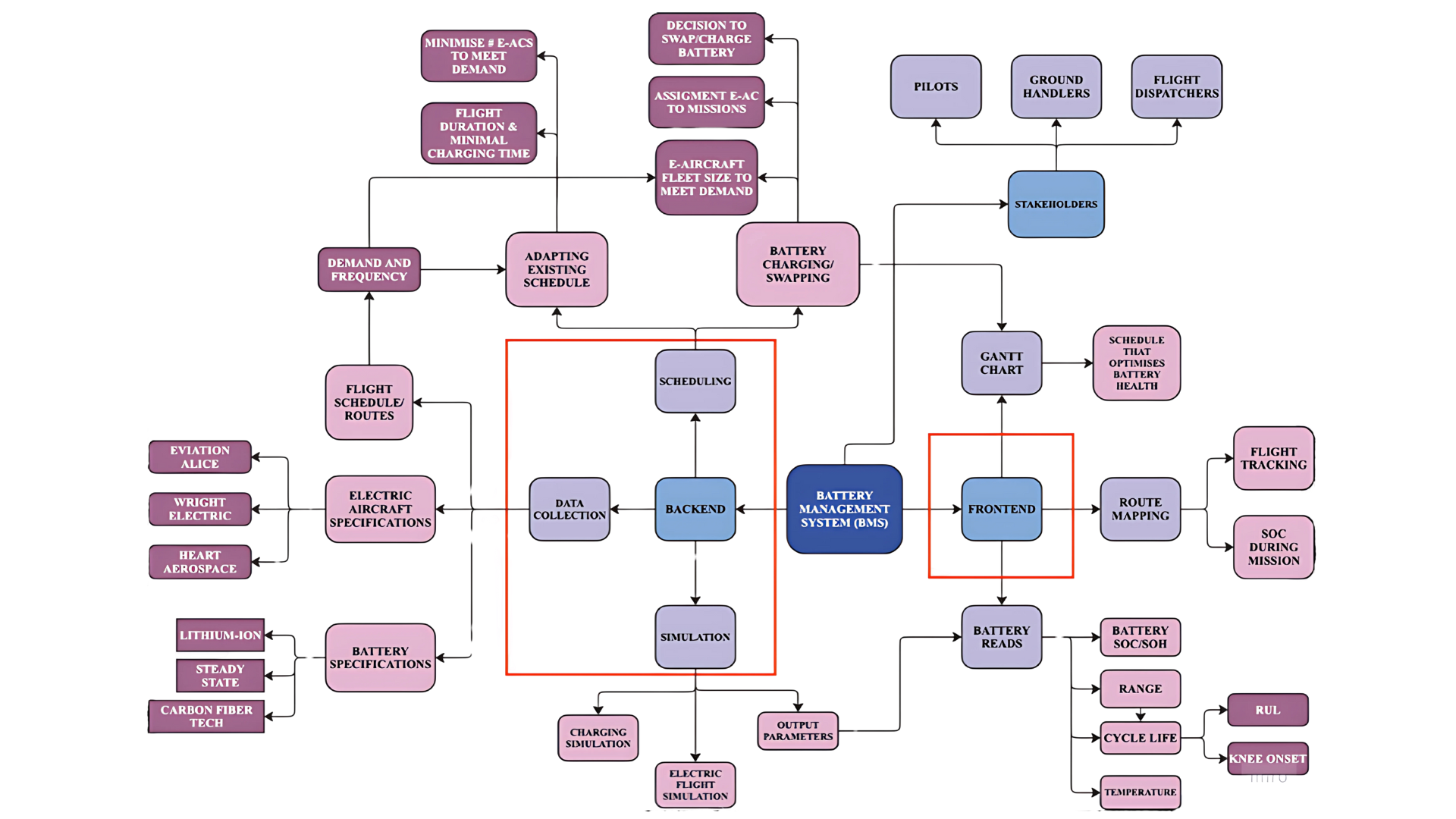

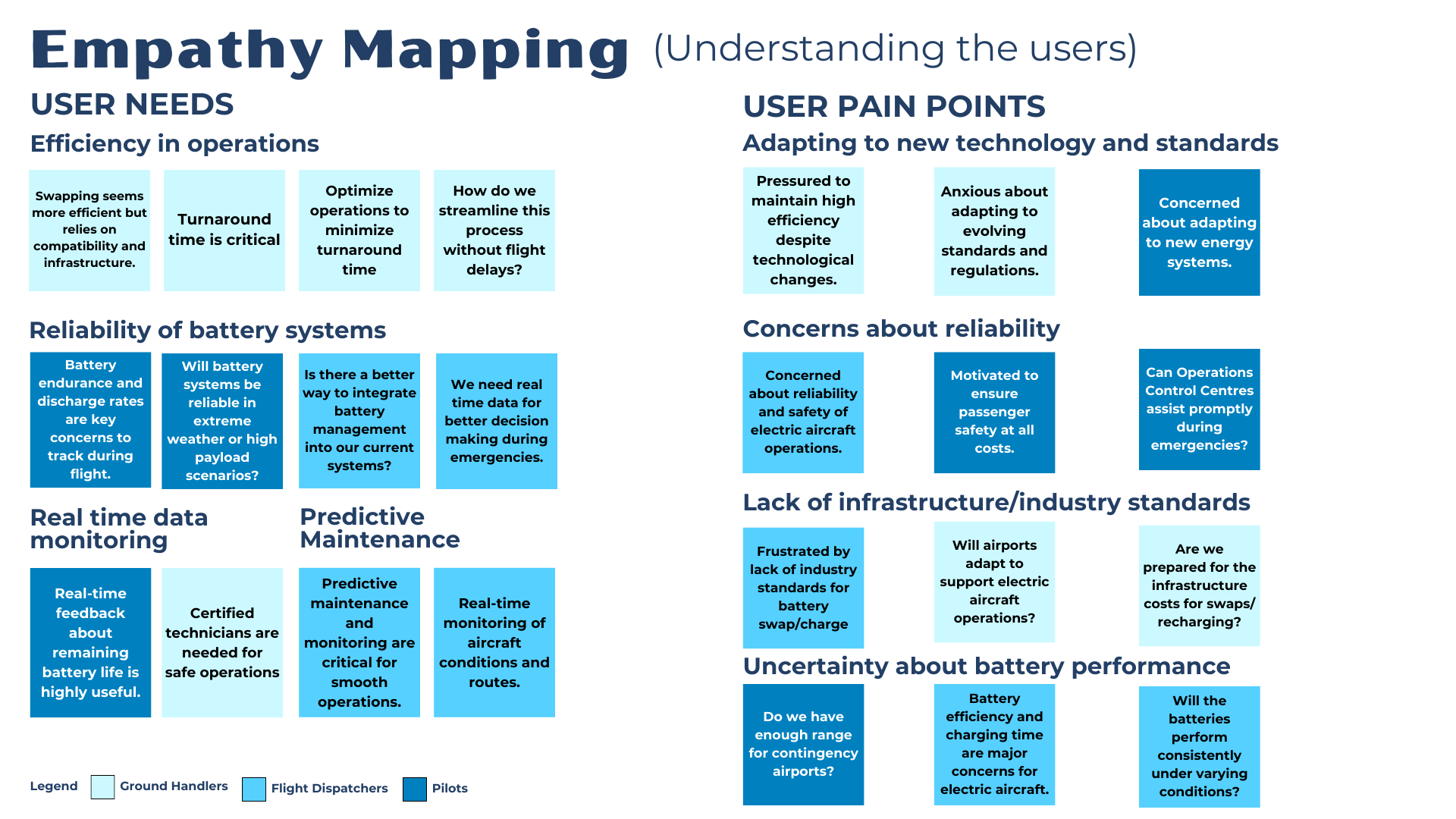

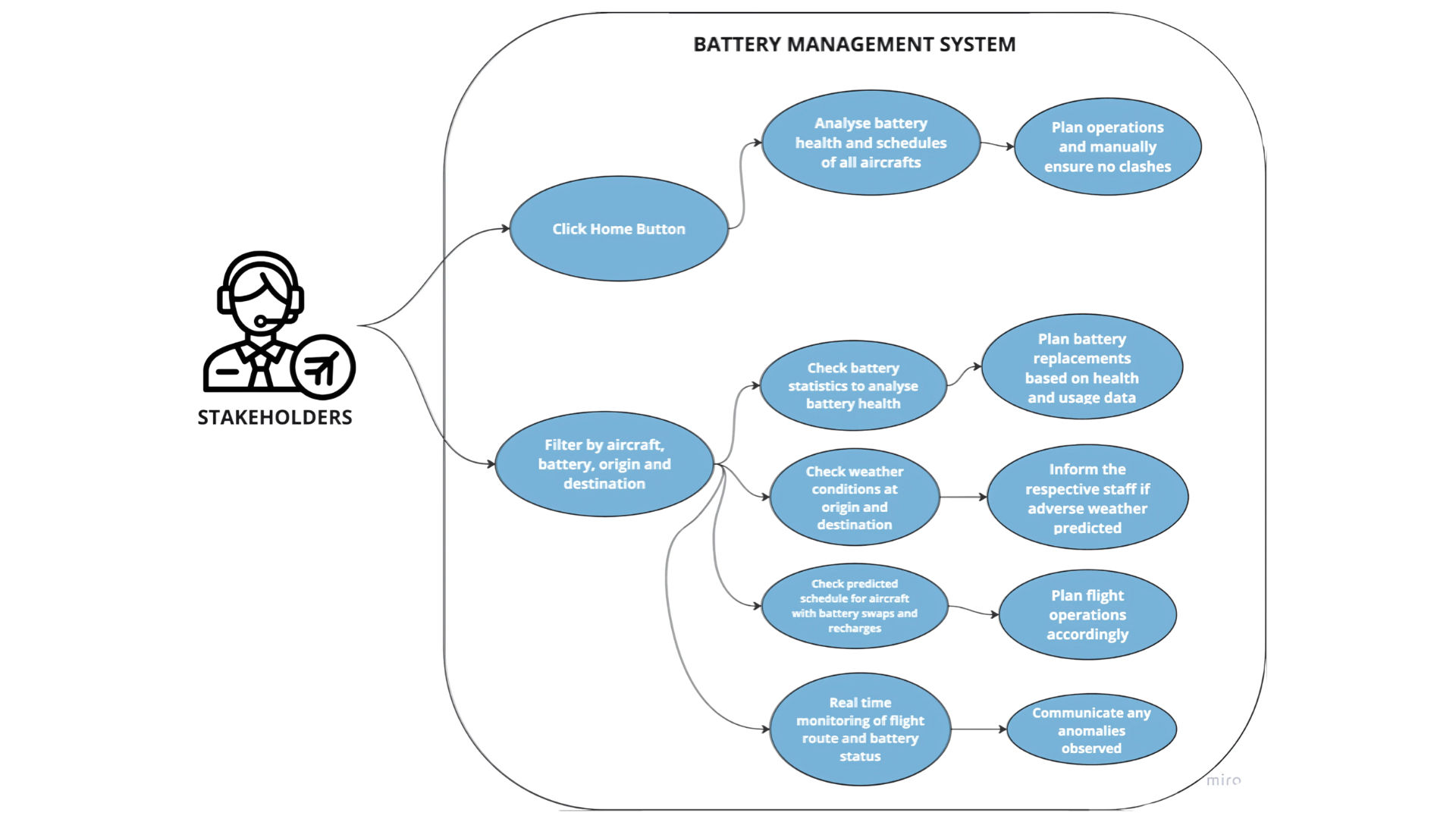

To address these challenges, we’re building a smart Battery Management System (BMS) that optimises flight routes for electric aircrafts while continuously monitoring battery health. By improving efficiency, extending battery lifespan, and minimising environmental strain, our solution empowers airlines to operate more sustainably and cost-effectively.

Batteries are at the core of electric aircraft propulsion and play a vital role within any battery management system.

We chose to focus on Lithium-Sulfur (Li-S) batteries due to their advanced capabilities and growing traction within the aviation industry.

Lithium-Sulfur batteries offer significant advantages over traditional lithium-ion options, with the potential to store up to five times more energy per unit of weight. Their lightweight properties make them especially well-suited for electric aircraft, and companies like Sion Power and Oxis Energy are already exploring their use in real-world aviation settings. In addition to improved energy density, Li-S batteries present a more cost-effective solution by utilising Sulfur instead of expensive rare-earth metals, making them a strong contender for sustainable and scalable airline adoption.

Efficient electric aircraft operations require more than just battery power — they demand smart scheduling that actively protects and extends battery health across flight missions.

While existing research, such as RISE’s MODELflyg project, offers valuable insights into electric flight scheduling through smart charging algorithms and infrastructure optimisation, it falls short by focusing on a single aircraft type and battery size, and by neglecting key battery health factors like degradation and State of Health (SoH).

Similarly, a study by Delft University of Technology proposes a two-phase optimisation model incorporating fleet sizing and battery swapping strategies, but it overlooks real-world variables such as charging profile accuracy and mission complexity.

To address these gaps, our Battery Management System (BMS) integrates health-focused metrics, supports diverse aircraft and battery configurations, for adaptive scheduling. This approach not only enhances battery longevity but also ensures the long-term sustainability and reliability of electric aviation.

We focused on three major electric aircraft types to integrate into our Battery Management System (BMS) software, ensuring a balanced scope that avoids oversimplification while managing data complexity. After evaluating over 10 companies, we selected these three based on their advanced development stages and strong airline interest:

- Eviation, an Israeli start-up, is developing Alice, a 9-seater electric aircraft, with over 600 letters of intent from major customers, including Cape Air and DHL.

- Heart Aerospace, a Swedish manufacturer, is working on the ES-30, a 30-seater hybrid-electric aircraft, with United Airlines committing to purchase up to 100 units.

- Wright Electric, a US-based start-up, is developing the Wright Spirit, a 100-seater aircraft, with partnerships from EasyJet and Viva Aerobus, positioning it for future demand in the commercial aviation sector.

These companies are at the forefront of electric aviation, making them ideal candidates for our BMS integration.

SUAVE models electric aircraft performance. This involves defining aircraft geometry, mass, propulsion (battery, motor, ESC, propeller), and mission segments (climb, cruise, descent). Existing aircraft, battery, and airport data (wingspan, weights, thrust, energy density, altitude, range) is validated. SUAVE then refines aircraft parameters (weights, range, power reserve) and simulates custom electric-specific missions, outputting crucial flight performance and energy data.

- Flight Conditions: Captures mission parameters like altitude profiles, airspeed variations, and climb/descent rates, crucial for aircraft performance evaluation.

- Aerodynamic Metrics: Includes detailed aerodynamic insights such as lift, drag, and moment coefficients, which are fundamental for understanding flight efficiency and stability.

- Battery Metrics: Provides critical battery-specific parameters like state of charge (SOC), energy consumption patterns, battery temperature profiles, and voltage fluctuations throughout the entire mission, directly affecting flight range and endurance.

Simulating electric and fuel-based aircraft are explicitly different, with electric aircraft significantly impacted by battery characteristics such as energy density, thermal limitations, discharge behaviour, and overall propulsion efficiency rather than fuel-flow dynamics. Insights drawn from the SUAVE eVTOL tutorial further clarified these distinctions, enhancing understanding of electric powertrain operations, mission-specific energy optimisation strategies, and long-term battery life cycle considerations in electric aviation.

This optimisation algorithm is designed to optimise electric aircraft operations by integrating data-driven models into a unified scheduling framework. It takes user inputs, SUAVE aircraft parameters, and demand forecasts, and uses a scheduling loop powered by regression and classification models to generate all feasible flight schedules. The goal is to find the most efficient schedule with minimal battery degradation over a given timeframe. The best schedule is then selected and stored for backend use.

The consumption model predicts the energy usage during every flight segment, depending on the estimated battery consumption across all five flight phases: takeoff, climb, cruise, descent, and landing.

It accounts for flight distance, phase-specific consumption rates, and battery capacity to compute phase-wise energy demands. In addition to the simulated data ingested, we add additional noise to improve model robustness.

We do not factor in taxi distance in our calculations, and instead provide a safety margin for taxi and diversion-related purposes. This helps ensure that energy predictions are realistic and robust, supporting the generation of safe and feasible flight schedules.

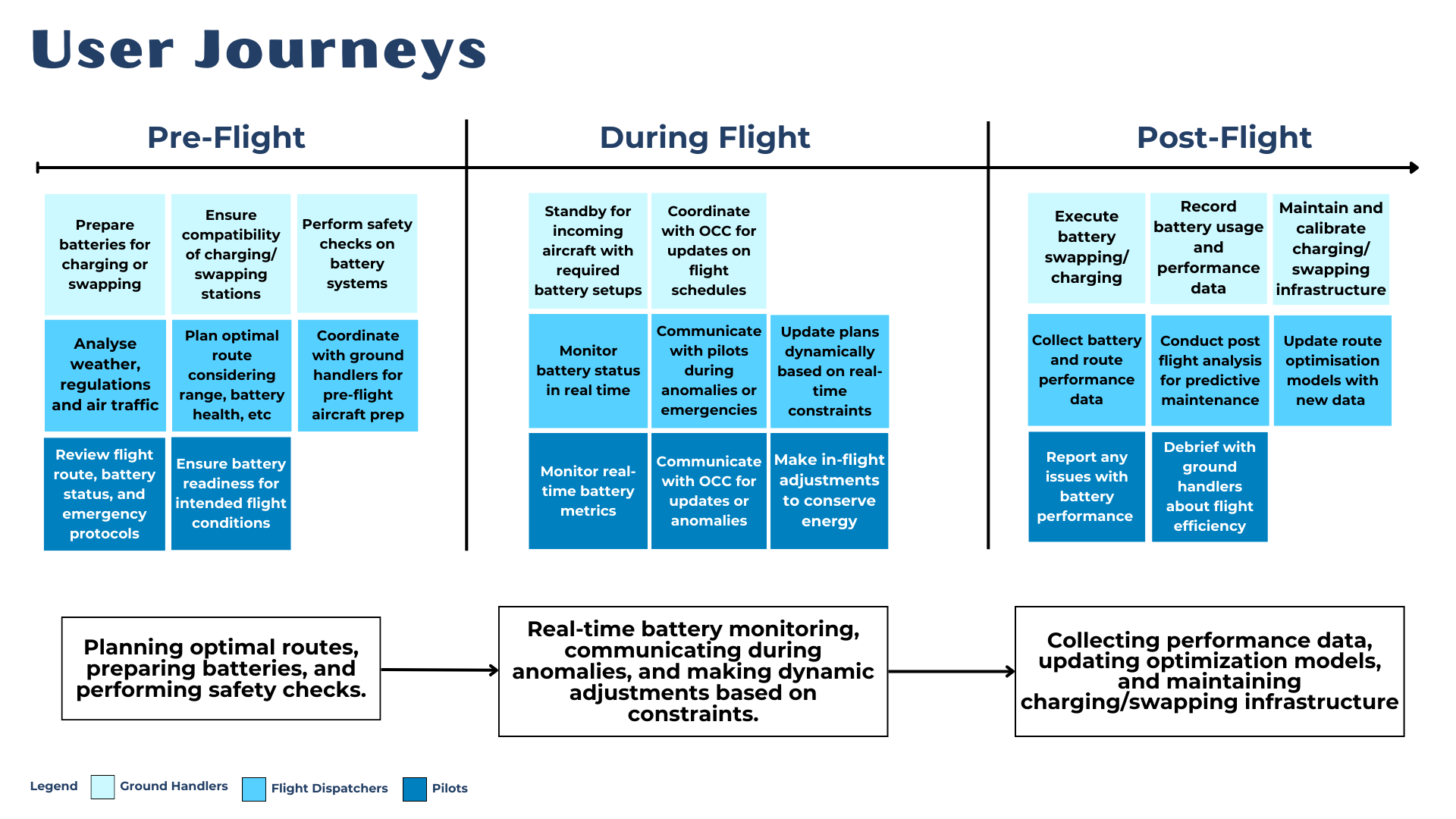

The decision model assists in determining the appropriate turnaround action after each flight segment—whether the aircraft should continue, charge, swap batteries, or undergo a forced swap. It takes into account real-time parameters like State of Charge (SoC), State of Health (SoH), distance, and time factors. Within the Scheduling Loop, it functions as a classification model that uses post-flight metrics and time windows to make optimal decisions. This model ensures the aircraft maintains safe energy margins throughout operations and dynamically adapts turnaround strategies based on health indicators and consumption history.

The demand model forecasts passenger or cargo demand between airport pairs, with variations based on both the day of the year and hour of the day. It uses sinusoidal functions to simulate seasonal trends and time-of-day consumption fluctuations. As shown in the diagram, this model feeds directly into the scheduling loop to influence the selection of destination airports, helping prioritise high-demand routes. It enhances the realism and responsiveness of the system by ensuring schedules are both technically feasible and aligned with user demand patterns.

At the core of the system is the Schedule Optimiser, which generates and evaluates all possible flight paths over a specified period (e.g., 24 hours). Starting from the user's selected aircraft and route, it iteratively selects valid destinations, evaluates energy consumption using the regression model, and applies decision logic to determine battery management strategies. The optimiser continuously updates metrics such as SoC, SoH, and remaining range, storing flight segments as part of the cumulative schedule. It then scores each possible schedule based on total battery degradation and selects the optimal one. This final schedule is stored and can be used for execution or further simulation.

To store Optimisation Model outputs, both relational (RDBMS) and non-relational (DBMS) databases were assessed across four criteria: data structure, integrity, scalability, and query language. RDBMS was chosen as the most suitable due to its strengths in relational data management and standardised queries. Within RDBMS options, PostgreSQL, SQL, and Microsoft SQL Server were further evaluated, with PostgreSQL emerging as the best fit based on its advanced features, scalability, data integrity, and support for complex schemas.

The backend APIs are built using FastAPI, a modern web framework for building performant and type-safe backend services in Python. FastAPI's intuitive structure, automatic validation with Pydantic, and built-in support for async operations made it ideal for developing efficient and scalable endpoints.

The API endpoints defined allow users to:

- Add and delete aircraft with appropriate battery associations.

- Retrieve all aircraft stored in the system.

- Get detailed battery specifications, including type, power, voltage, energy density, and total cycles.

- Fetch flight schedules associated with specific aircraft.

- Access battery metrics (SoC, SoH, temperature, and remaining range) recorded during a specific flight schedule segment.

Additionally, the data stored in the backend comes from the optimisation model, such as predicted demand for a flight, battery swap/recharge required, and other battery metrics predicted during flight (like SoC, SoH). These results are stored alongside flight schedule data and will be served to the front end via APIs for visualisation and user interaction.

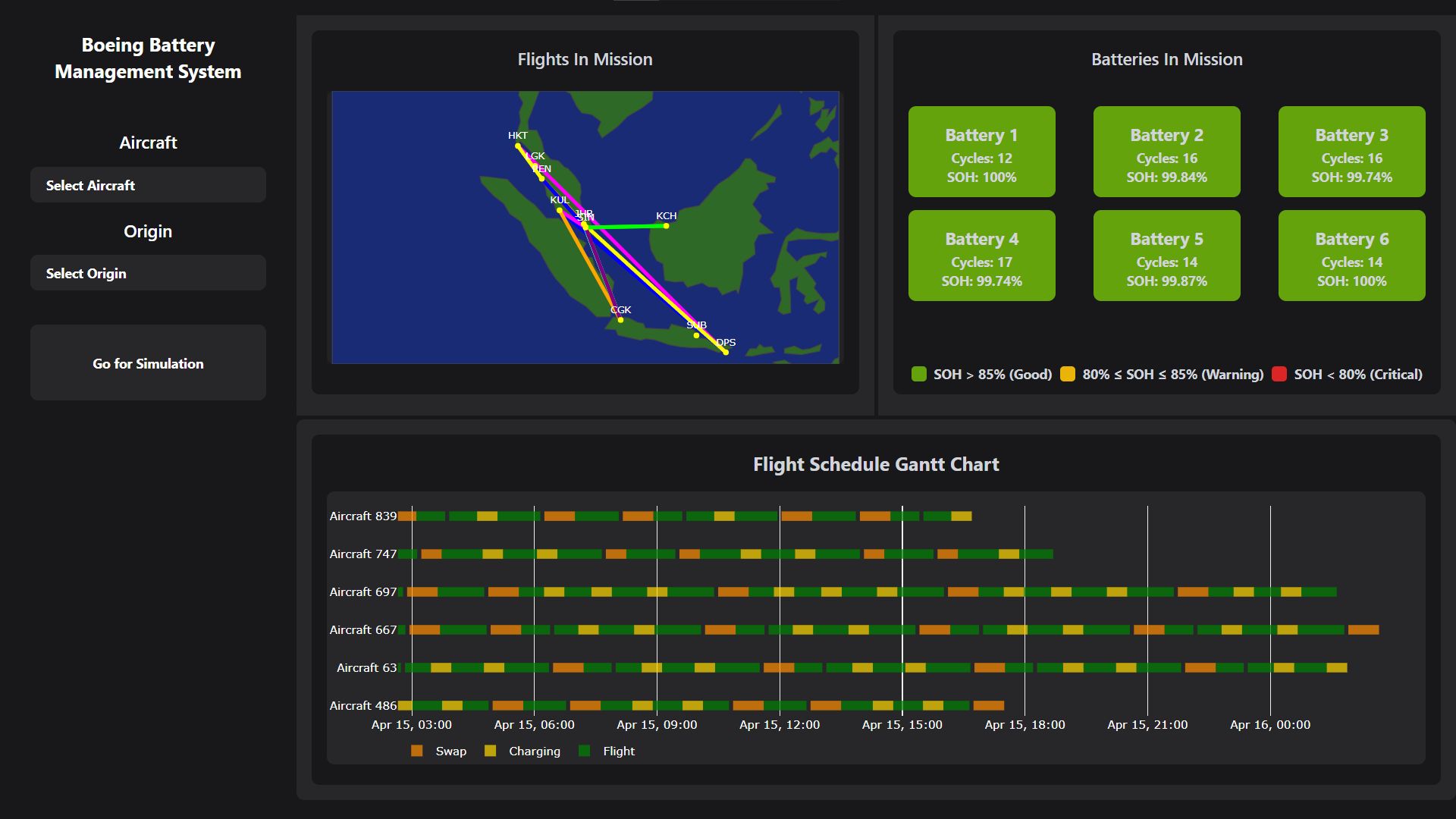

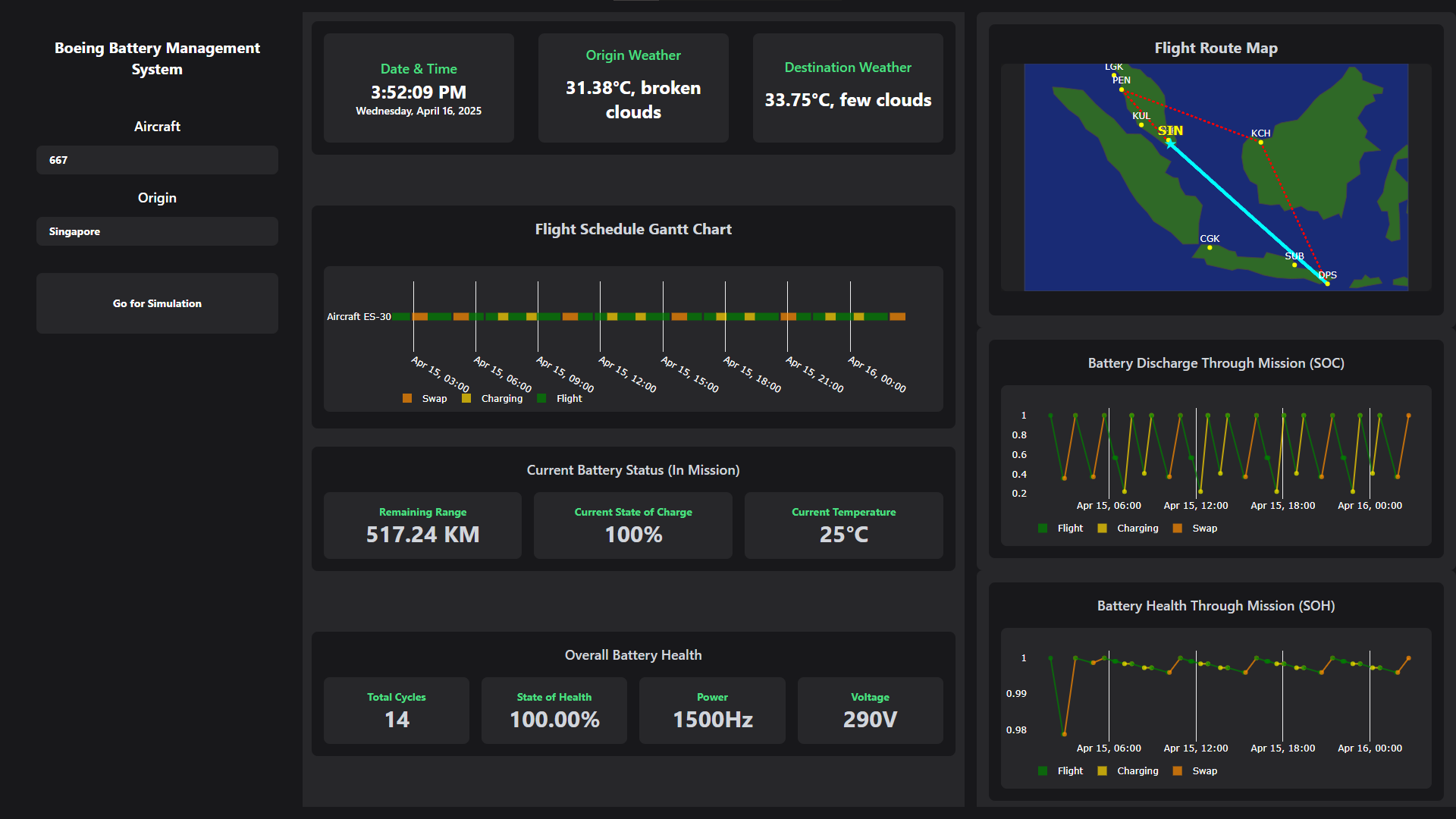

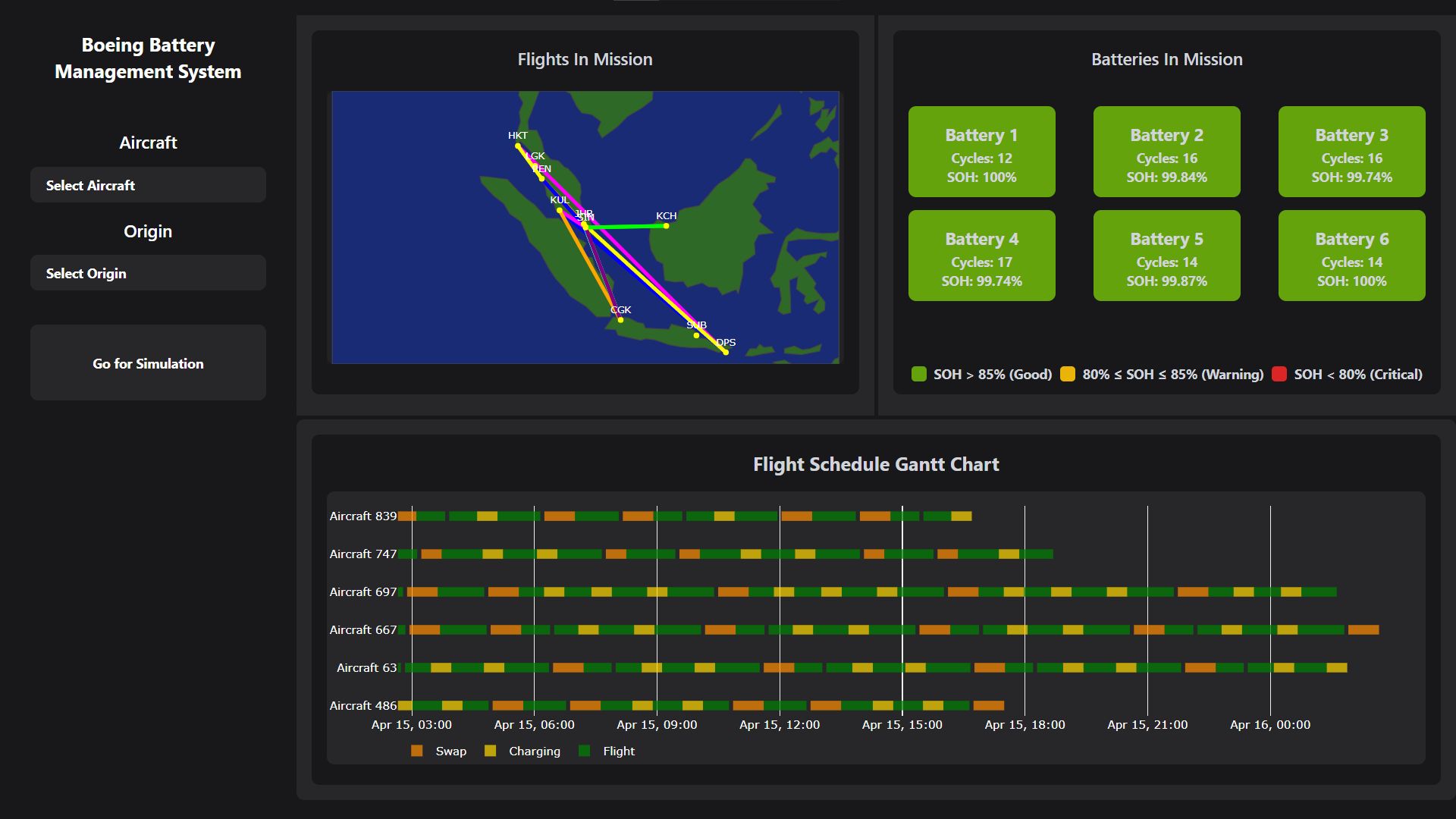

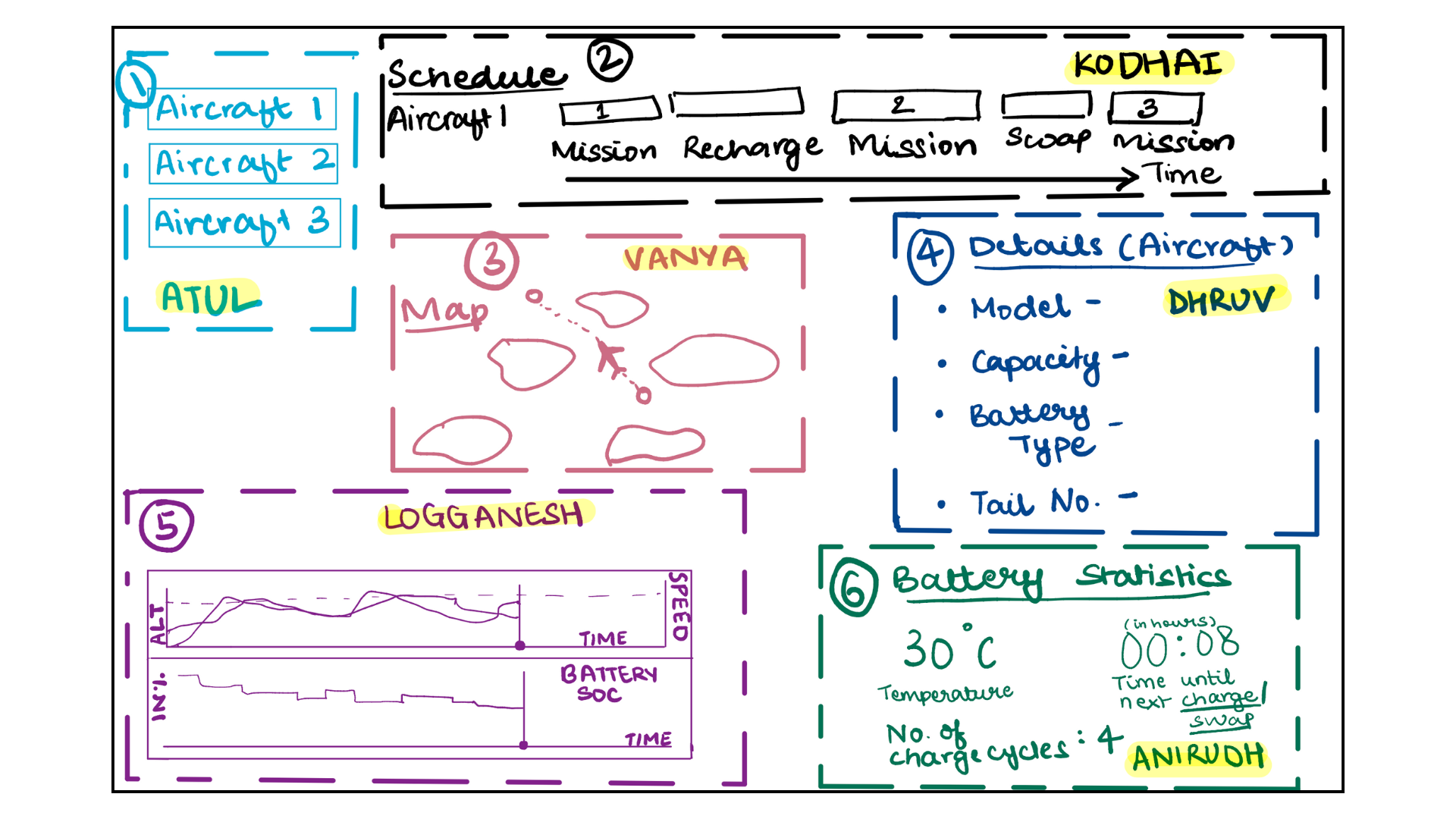

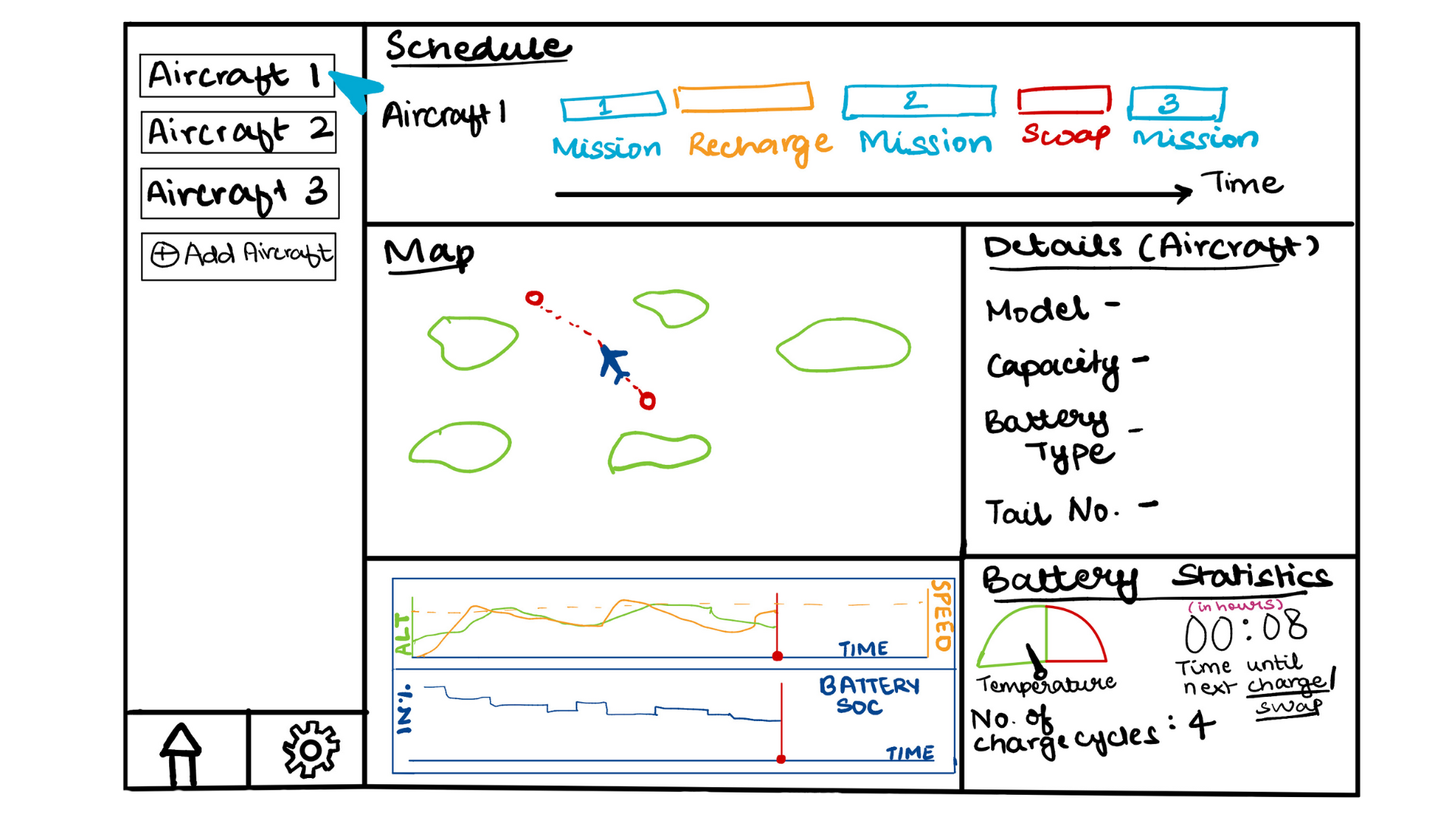

DROPDOWN

Allows user to choose the aircraft and the origin

"GO FOR SIMULATION"

This will redirect to a simulation page, where user can select aircraft type, origin and destination airports to generate the optimal flight schedule

FLIGHT ROUTE MAP

Shows the aircraft's mission on the map

BATTERY READS

Shows the current battery status in mission (remaining range, current state of charge/temperature) and the overall battery health (state of health, power and voltage)

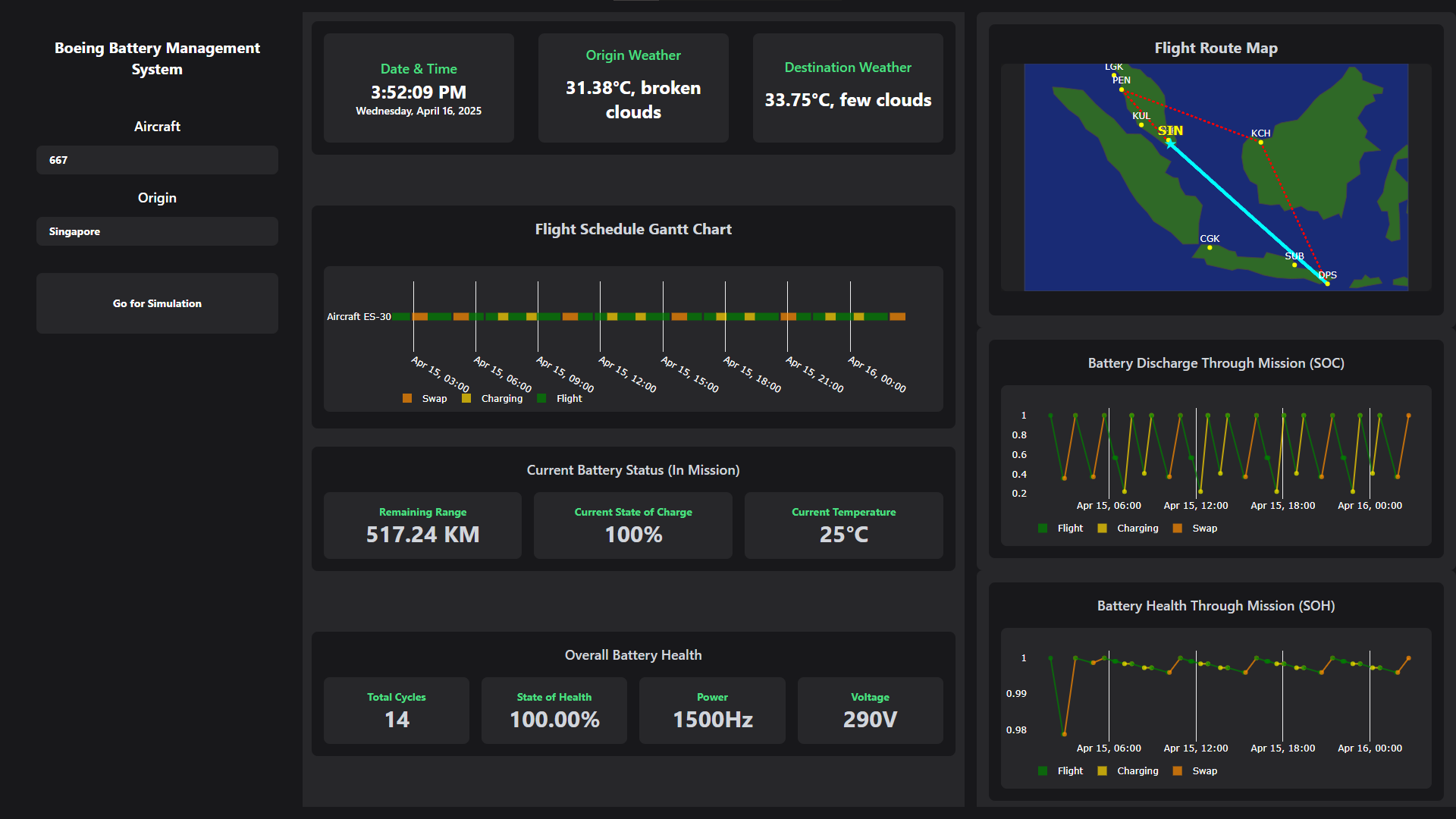

FLIGHTS AND BATTERIES IN MISSION

Shows the status of all the flights (on the map) and batteries (battery reads)

FLIGHT SCHEDULE GANTT CHART

Provides an overview of the optimal flight schedule with battery charge and swap opportunities

Prof Carlos Gerardo Murguia Rendon – We would like to sincerely thank Prof. Carlos for his incredible support and guidance, especially considering he joined the project midway through the term. Despite coming in midway, he readily offered his time and insight, helping us explore the right areas and potential solutions when we faced challenges. His thoughtful suggestions and steady encouragement were invaluable throughout the term, and we’re truly grateful for his mentorship.

Prof Francisco Benita – We extend our heartfelt gratitude to Professor Francisco Benita for his invaluable guidance throughout Term 7. His expertise in breaking down complex problems and encouraging us to explore various design alternatives has been instrumental in fostering our innovative solutions. Thank you, Professor, for pushing us to achieve excellence.

Prof Song Qun – We are deeply grateful to Professor Song Qun for inspiring us to think critically about our project and making us constantly question our proposed solutions till they become better. Her insights into different sub-systems and software architectures have been invaluable, providing a fresh perspective and guidance that has significantly influenced our direction and helped us achieve our deliverables.

Dr. Susan Wong (CWR Mentor) – We would like to express our sincere gratitude to Dr. Susan for her numerous tips on project management such as task allocation, timelines, and people management. Her invaluable advice on presentation and audience-oriented content as well as her constant availability for consultation has greatly enhanced our work, whether for presentations, reports or poster. Thank you, Dr. Susan, for your continuous support and guidance.

Rahul Ashok, Sustainability Innovation Lead at Boeing – We would like to express our sincere gratitude to Rahul for his exceptional guidance and insights. His expertise in sustainable aviation technologies and generous support have been instrumental in shaping our research and understanding of innovative aerospace solutions.

Ayodeji Akinola, Researcher: Sustainable Aviation Strategy – We extend our heartfelt appreciation to Ayodeji Akinola for his profound knowledge and unwavering support. His strategic insights, constructive feedback, and dedication to advancing sustainable aviation have significantly enriched our project.

Other Team Members from Boeing – We extend our appreciation to our Boeing team members for their collaborative support, technical expertise, and invaluable contributions to our research in sustainable aviation. Their insights, guidance, and commitment have been instrumental in advancing our project’s goals and understanding of innovative aerospace solutions.